DHS Series Dual Hall Switch

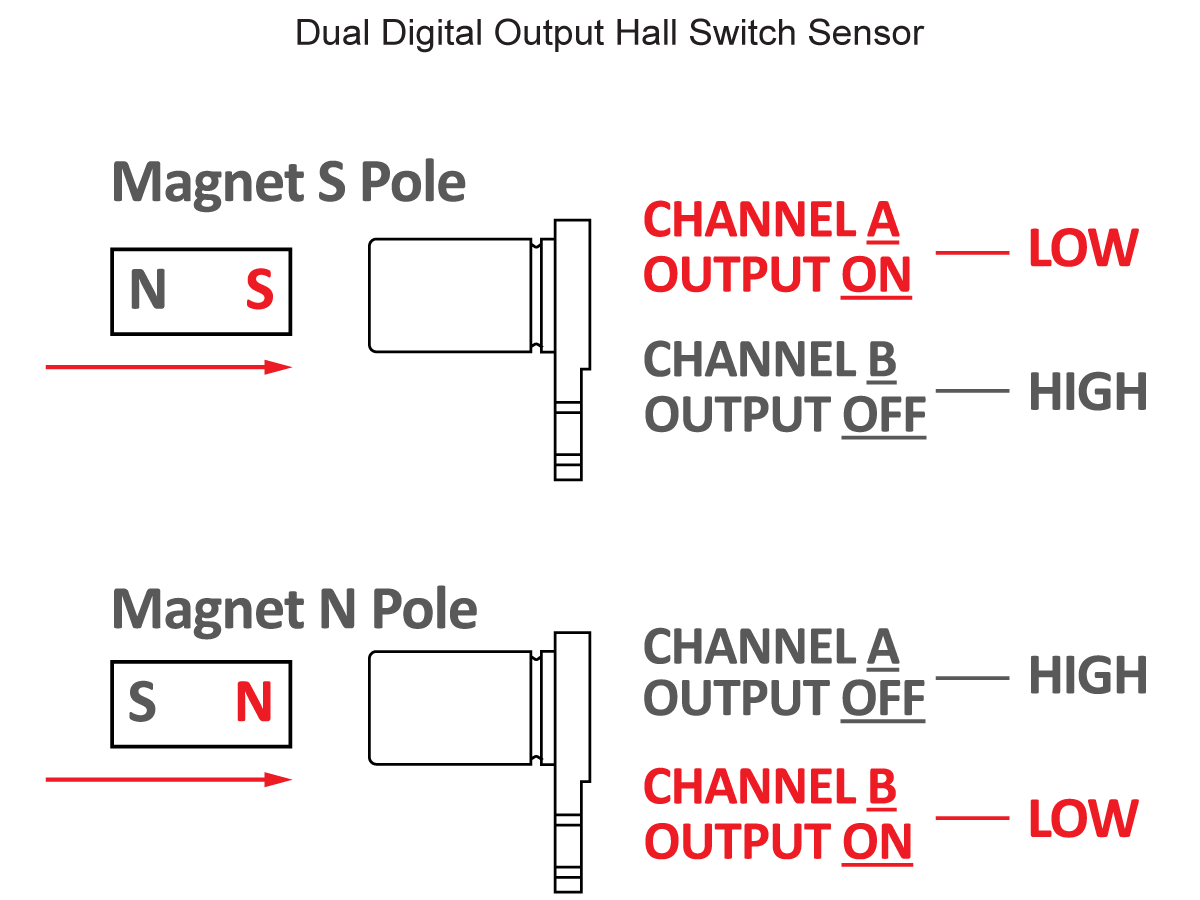

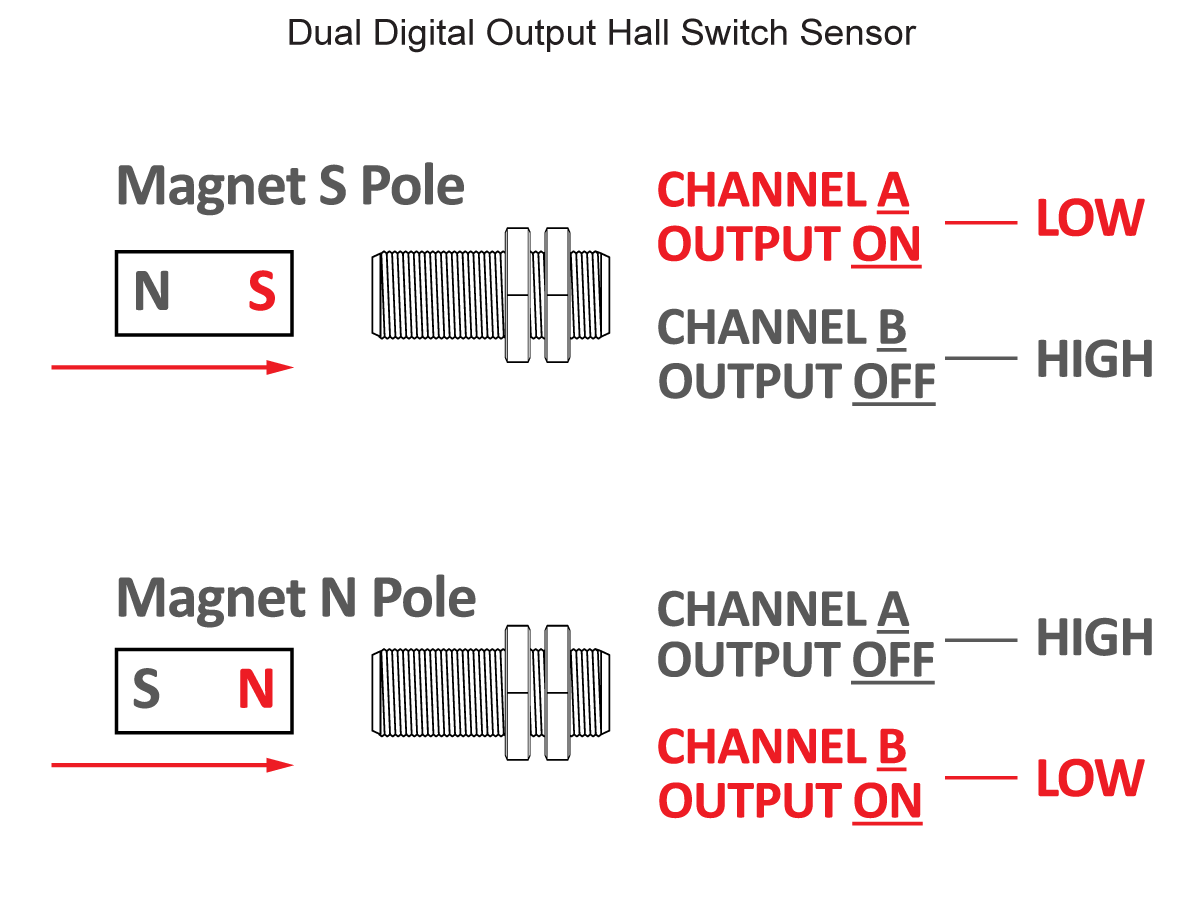

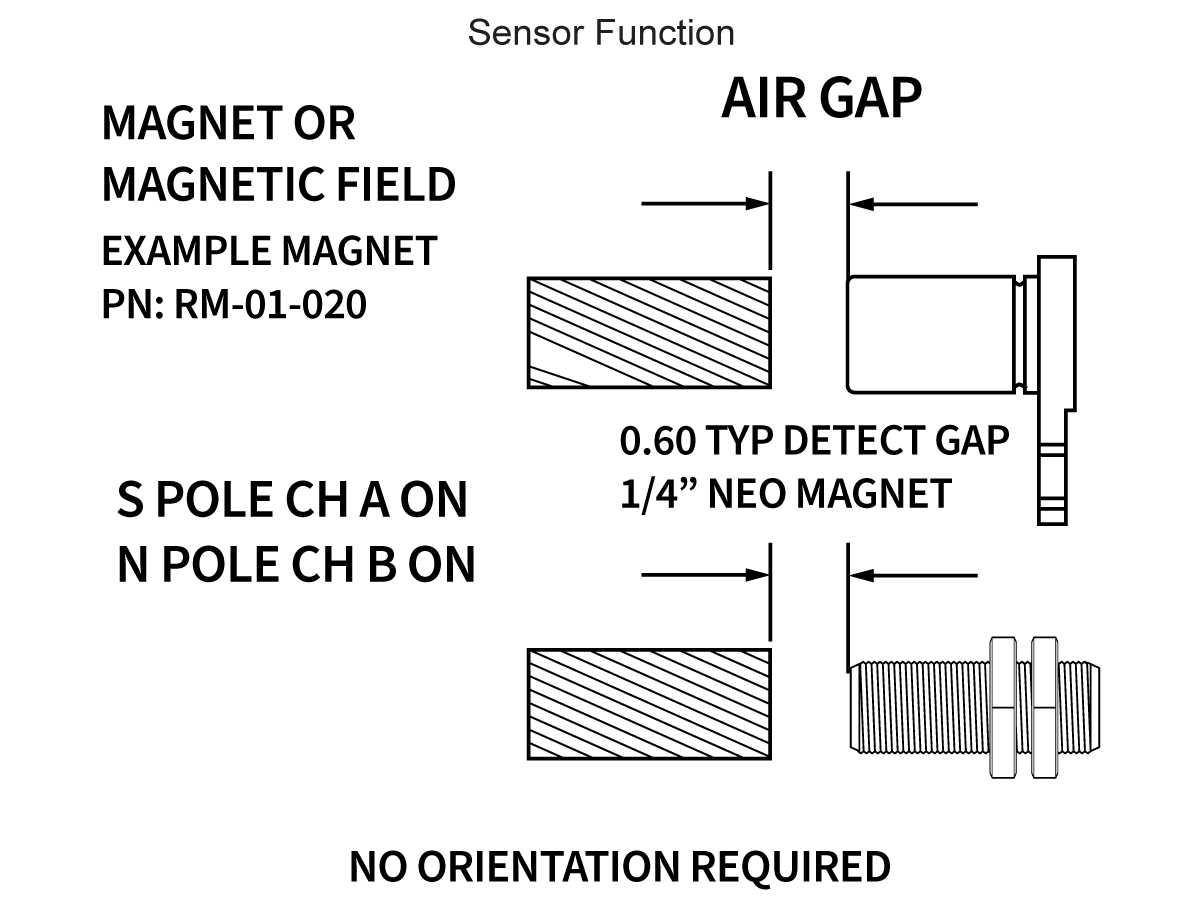

The DHS series delivers reliable, non-contact magnetic sensing with dual digital outputs for directional feedback. Designed to detect both north and south pole magnetic fields, DHS sensors function as directional limit switches, ideal for applications requiring position tracking, motion control, or directional confirmation.

Built on solid-state Hall effect technology, DHS sensors offer bounce-free operation, internal hysteresis, and stable performance across wide temperature ranges. With rugged housings and flexible connection options, they’re engineered for durability in automotive, industrial, and agricultural environments.

Standards and Certifications

- Dual digital outputs for directional feedback (Channel A & B)

- Omnipolar magnetic detection (north and south pole sensitivity)

- Non-contact, solid-state design for long-term reliability

- Bounce-free operation with internal hysteresis

- Wide operating temperature range for harsh environments

- Compact housings: molded, aluminum, stainless steel

- Easy installation with threaded or flange mount options

- Ideal for directional limit switching, position tracking, and automation systems

- Wide range of connector options with free end wires, cable harnesses with connectors, or integrated connectors

| Output Type | NPN |

| Actuator Material | Magnet |

| Frequency | 50 kHz |

| Supply Voltage, Vcc | 4.2 ~ 24V |

| Operating Temp. | -40 ~ 110 C |

| Package/Case | Stainless Steel Cylinder, Threaded Aluminum Cylinder, Threaded Plastic Cylinder, Threaded Plastic, Flange Mount |

| Termination Style | Integrated Connector, Cable Harness with Connector, Free End Wire |

- Min/max position detection

- Confirm alignment or proximity of bins/carts/trays in manufacturing lines

- Provide count feedback of components in production and testing

- Resolve speed of industrial and agricultural attachments

- Shaft and gear speed in agricultural equipment

- Monitors speed in conveyor systems and assembly lines

- Speed resolution in automation equipment

- Measure feed rate of cranes and winches

- Resolving engine RPMs

- Measuring vehicle/wheel speed

- Pulley systems in manufacturing

- Monitoring gears in transmissions

- Cam and Crank shaft timing