Driving Innovation in Modern Mobility: Reed Switches, Sensors, and Relays for Every Mode of Motion

From Road to Rail, Sea to Sky—We Engineer What Moves the World

In today’s fast-moving and interconnected transportation landscape, the demand for intelligent, dependable safety and control systems is more vital than ever. From ensuring the integrity of electric vehicle platforms and rail networks to enhancing maritime and aerospace operations, transportation applications require components that are rugged, responsive, and built to perform under extreme conditions.

At Standex Detect, we design rugged, intelligent reed switches, sensors, and relays that ensure real-time monitoring, automation, and reliability across all modes of modern transportation.

Whether it’s detecting anomalies in vehicle access systems, monitoring hydraulic levels in braking systems, or enabling motion control in autonomous navigation platforms, our portfolio is designed to support the evolving needs of transportation safety and performance. With a focus on long operational life, energy efficiency, and high reliability, our components are trusted by OEMs and system integrators worldwide.

Technology Portfolio for Transportation

- Reed Switches: Passive, hermetically sealed, and ideal for harsh environments

- Reed Sensors: Contactless position and proximity detection with no power draw

- Hall Effect Sensors: Solid-state, analog/digital output for speed, angle, and position

- Reed Relays: High-voltage isolation, low contact resistance, compact footprint

- Optocouplers: Electrical isolation and EMI protection in high-voltage systems

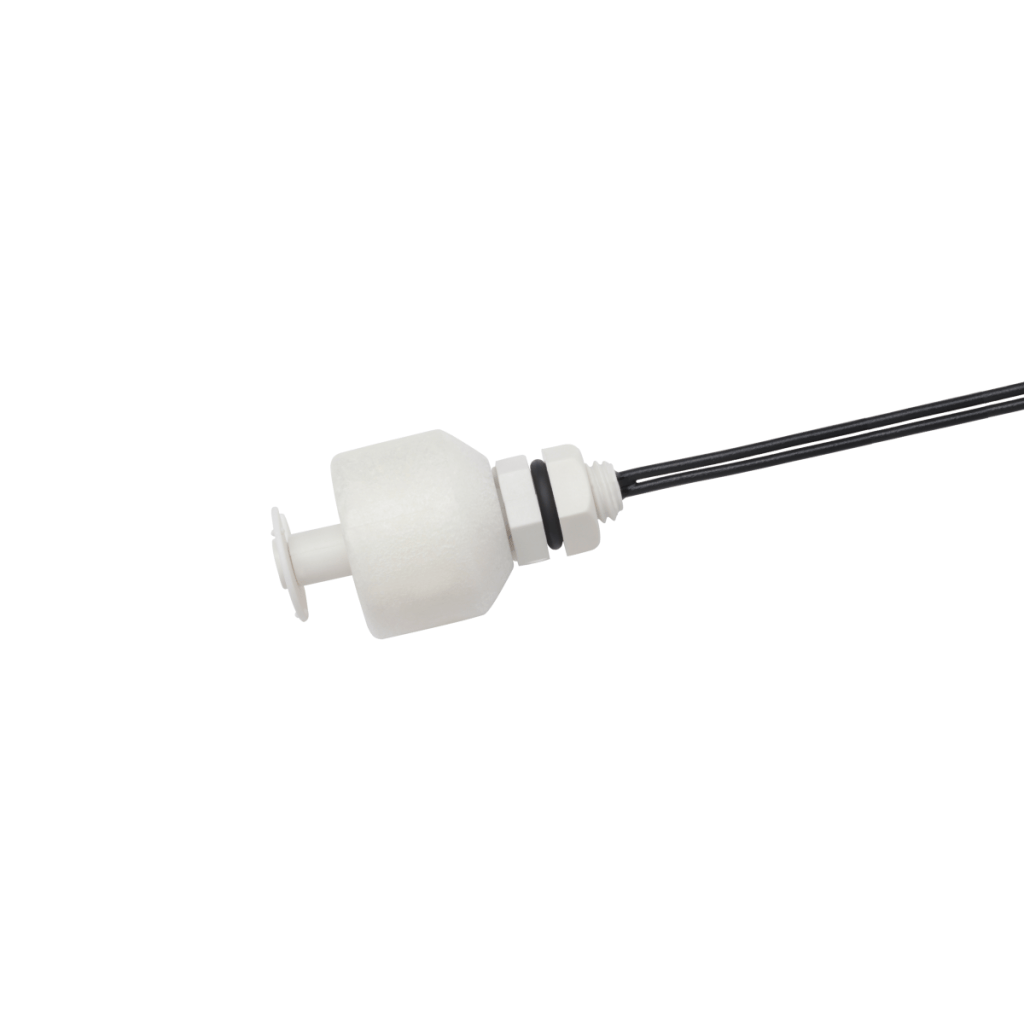

- Fluid Level Sensors: Reed, Hall, and water-in-fuel sensors for single/multi-point detection

- Gear Tooth Sensors: Speed, direction, and quadrature sensing for rotating components

Engineering the Backbone of Modern Mobility

Standex Detect: Your Engineering Partner in Modern Mobility

At Standex Detect, we don’t just manufacture components, we become an extension of your engineering team. Through our Innovate | Consult | Engineer | Deliver approach, we collaborate with OEMs and Tier 1 suppliers to co-engineer scalable, reliable solutions that meet the demands of electrification, automation, and ruggedization across road, rail, sea, and air.

Our approach is built on four pillars that guide every engagement:

- Innovate: Generate new ideas and concepts that solve emerging challenges in electrification, automation, and ruggedization.

- Consult: Understand client needs and requirements through open dialogue and technical intimacy.

- Engineer: Create effective and tangible solutions through deep technical collaboration and application expertise.

- Deliver: Ensure customer satisfaction with solutions that meet performance, quality, and delivery expectations.

Whether you’re designing for road, rail, sea, or sky, we bring the agility, customization, and global support needed to help you succeed.

What Sets Us Apart:

- Engineer-to-Engineer Collaboration: We work directly with your technical teams to co-develop solutions that fit your exact specifications.

- Vertically Integrated Manufacturing: From reed switches to custom sensor assemblies and relays, we control the entire production process for quality and speed.

- Agile Global Supply Chain: With 18 sites across 3 continents, we offer local support, redundancy, and rapid response to changing demands.

- Custom + Standard Solutions: Whether you need off-the-shelf components or fully customized assemblies, we deliver both with precision and speed.

Why Transportation OEMs Choose Us:

- Custom Engineering: Tailored from component to full assembly for mobility platforms.

- Agility & Speed: Fast response to design changes and market demands.

- Reliability: Built to withstand extreme temperatures, vibration, and environmental exposure.

- Scalability: Supporting everything from prototypes to global production.

- Innovation: Smart sensors, miniaturization, and integration for next-gen transportation.

Certified, Reliable, and Customizable Components for Every Mode of Motion

Certifications & Compliance

We meet or exceed globally recognized standards to ensure the safety, reliability, and performance of our reed switches, sensors, and relays across a wide range of transportation platforms, from electric vehicles to aerospace and marine systems:

General Transportation:

ISO 9001:2015 – Quality Management System

ISO 14001:2015 – Environmental Management System

REACH & RoHS – Compliance with hazardous substance and environmental regulations

CE Marking – Conformity with EU safety, health, and environmental protection standards

IP67/IP68 Ratings – Environmental protection for components exposed to dust, water, and vibration

Passenger Automotive:

IATF 16949:2016 – Automotive Quality Management System for design and manufacturing of automotive components

E-Vehicles:

UL Certifications – For reed switches, sensors, and relays used in electric drivetrains and auxiliary systems

Aerospace & Aviation:

AS9100 – Quality Management System for aerospace applications

NASA NHB 8739.3 – Workmanship standard for high-reliability soldered electrical assemblies

MIL-STD-202, MIL-STD-981, MIL-PRF-27 – Military standards for environmental testing, hybrid microcircuits, and magnetic components

Marine & Naval:

IP67/IP68 Ratings – Protection against water ingress and corrosion in marine environments

Case Study

Enhancing Safety in Utility Vehicles with Hall Effect Sensors

A leading manufacturer of landscaping, construction, and utility vehicles needed a reliable way to ensure safe engagement of the Power Take-Off (PTO) system. Incorrect PTO activation could lead to serious safety hazards and equipment damage.

Challenge:

Prevent PTO engagement unless the drive shaft was rotating in the correct direction and above a minimum speed.

Solution:

Standex provided custom Hall Effect gear tooth sensors that detect shaft rotation and direction. These sensors are rugged, compact, and operate reliably in harsh environments.

Outcome:

- Improved vehicle safety and performance

- Reduced maintenance needs

- Cost-effective and long-lasting solution