Powering Productivity: Smart Solutions for the Machines That Build and Grow

Rugged by Design: Reed Switches, Sensors, and Relays That Powers the Job Site

In the world of construction and agriculture, equipment is expected to perform reliably in some of the harshest conditions imaginable. From dusty fields and muddy job sites to extreme temperature swings and constant vibration, these environments demand components that are not only rugged but also intelligent and adaptable. As the industry shifts toward electrification, automation, and precision control, the need for robust reed switches, sensors, and relays has become more critical than ever.

At Standex Detect, we engineer solutions that meet these challenges head-on. Our products are designed to thrive in off-road and heavy-duty applications, delivering consistent performance where failure is not an option. Whether it’s ensuring safe operation of hydraulic systems, monitoring fluid levels in real time, or enabling advanced control in electrified drivetrains, our technologies help OEMs and system integrators build smarter, safer, and more efficient machines.

With a deep understanding of the demands of mobile equipment and a commitment to innovation, our portfolio supports the evolving needs of modern construction and agricultural machinery. Below is a comprehensive overview of our specialized offerings:

Technology Portfolio for Construction & Agriculture

- Reed Switches: Hermetically sealed and ideal for rugged outdoor environments, these passive components are used in safety interlocks, fluid level detection, and position sensing in tractors, loaders, and sprayers.

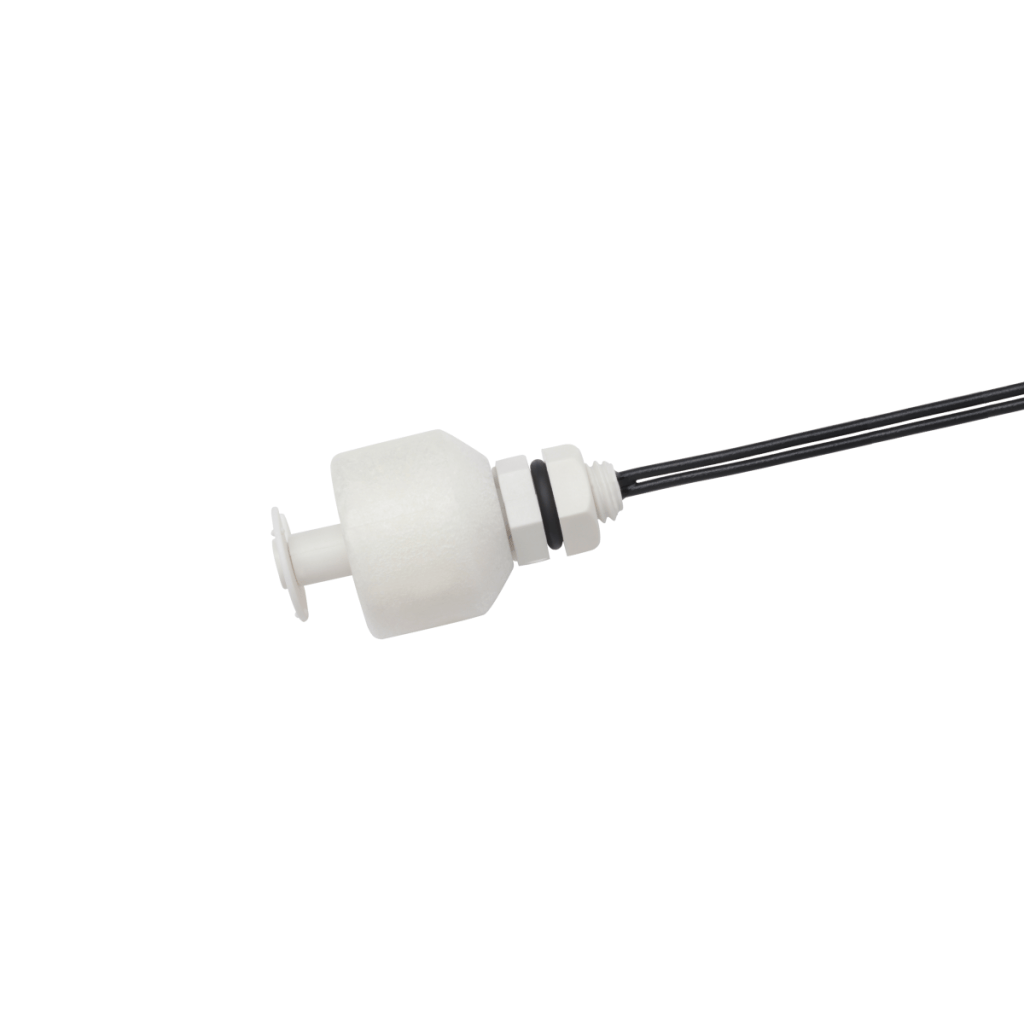

- Reed Sensors: Contactless, low-power sensors that provide reliable position and proximity detection in cab controls, storage compartments, and hydraulic systems.

- Hall Effect Sensors: Solid-state sensors offering analog or digital output for speed, angle, and position measurement, perfect for throttle control, steering angle sensing, and suspension monitoring.

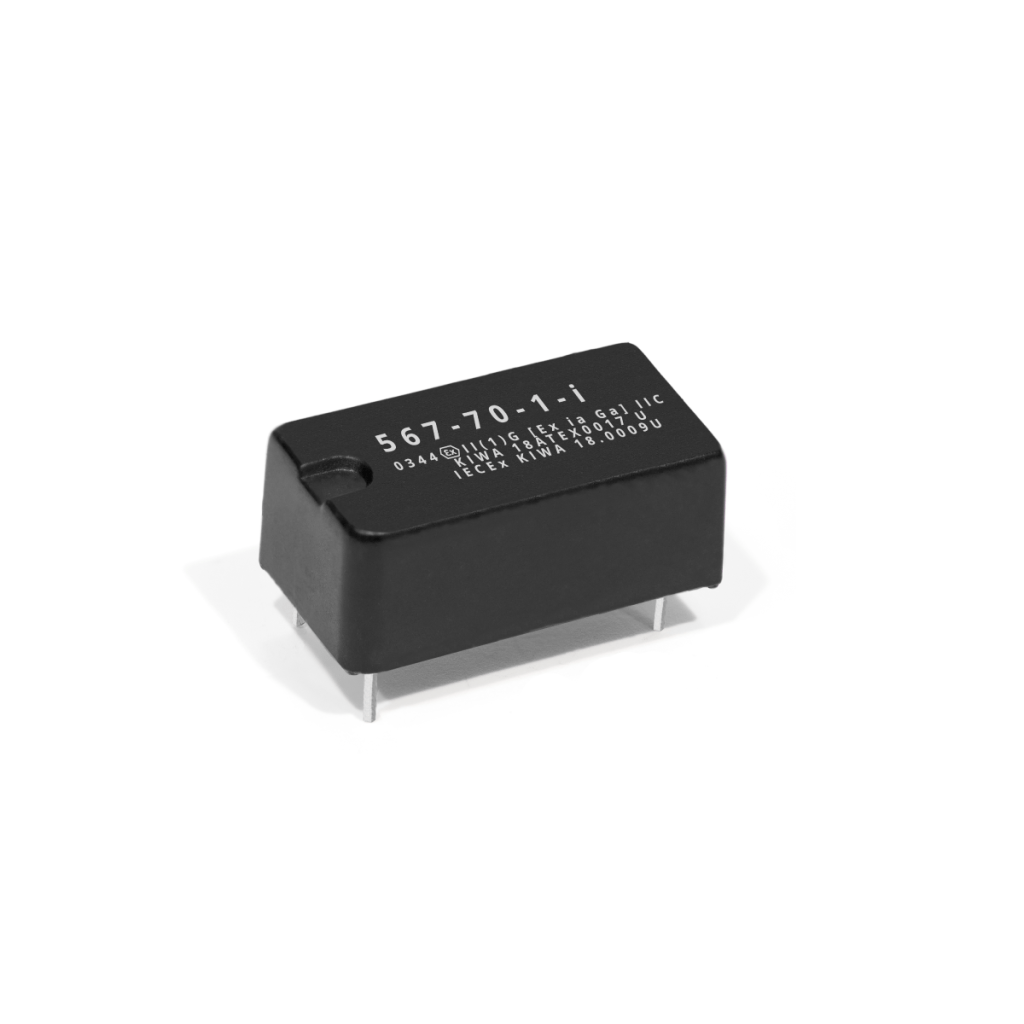

- Reed Relays: Compact and efficient, these relays offer high-voltage isolation and low contact resistance, ideal for switching power in electric drivetrains, heated seats, and auxiliary systems.

- Optocouplers: Provide electrical isolation and EMI protection in high-voltage systems, ensuring safe signal transmission in electrified and hybrid off-road equipment.

- Fluid Level Sensors: Available in reed, Hall, and capacitive configurations, these sensors monitor coolant, hydraulic fluid, DEF, and fuel levels in tanks and reservoirs.

- Gear Tooth Sensors: Detect speed, direction, and rotation of shafts and gears, critical for monitoring drivetrain components, PTOs, and rotating implements in agricultural and construction machinery.

Heavy-Duty Innovation: Enabling Automation and Electrification in Construction

At Standex Detect, we go beyond supplying components—we become your engineering partner. Through our Innovate | Consult | Engineer | Deliver model and a deeply collaborative, engineer-to-engineer approach, we help OEMs and equipment manufacturers bring smarter, safer, and more rugged off-road systems to life.

Our approach is built on four pillars that guide every engagement:

- Innovate: Generate new ideas and concepts that solve emerging challenges in electrification, automation, and ruggedization.

- Consult: Understand client needs and requirements through open dialogue and technical intimacy.

- Engineer: Create effective and tangible solutions through deep technical collaboration and application expertise.

- Deliver: Ensure customer satisfaction with solutions that meet performance, quality, and delivery expectations.

Whether you’re designing for autonomous tractors, electric excavators, or precision sprayers, we bring the agility, customization, and global support needed to help you succeed in the field or on the job site.

Why Construction & Agriculture OEMs Choose Us:

- Custom Engineering: Rugged sensors and relays for heavy-duty machinery and precision farming.

- Agility & Speed: Quick response to seasonal production cycles and evolving standards.

- Reliability: Withstands vibration, dust, moisture, and temperature extremes.

- Scalability: From early prototypes to full fleet deployment.

- Innovation: Smart sensing and automation for connected, efficient, and sustainable equipment.

Engineering the Future of Construction: Precision Sensing for Harsh Environments

Certifications & Compliance

We meet or exceed globally recognized standards to ensure the durability, safety, and performance of our Reed switches, sensors, and relays in rugged off-road and agricultural environments:

General Construction & Agriculture:

ISO 9001:2015 – Quality Management System

ISO 14001:2015 – Environmental Management System

REACH & RoHS – Compliance with hazardous substance and environmental regulations

CE Marking – Conformity with EU safety, health, and environmental protection standards

Electric Systems:

UL Certifications – For reed switches, sensors, and relays used in electrified and auxiliary systems

Hazardous Monitoring Environments (e.g., fuel, DEF, hydraulic fluid):

ATEX & IECEx – Certified components for use in explosive or flammable environments

DIN EN ISO/IEC 80079-34 – Quality systems for explosive atmospheres

Case Study

Precision Grain Flow Monitoring with Ferrous Metal Detection Sensors

A major agricultural equipment manufacturer needed to detect four distinct positions of grain doors, open, closed, and two intermediate stages to optimize grain flow during loading.

Challenge:

Design constraints prevented the use of traditional magnet-based sensors.

Solution:

Standex developed a ferrous metal detection sensor using a reed switch and internal magnet, eliminating the need for external magnets.

Outcome:

- Accurate detection of all four door positions

- Easy installation and cost-effective design

- Improved grain flow control and operational efficiency

Literature

Click on a resource below to download it.