Clean, Safe, and Reliable: Reed Switches, Sensors, and Relays for Food & Beverage Systems

Built for Clean Environments: Sensors That Withstand the Washdown

Food and beverage processing environments demand components that meet strict hygiene standards while withstanding exposure to moisture, chemicals, and high-pressure washdowns. From production lines to packaging systems, every sensor and relay must operate reliably without compromising food safety. Standex Detect offers sealed, corrosion-resistant solutions engineered for food-grade applications, ensuring accurate monitoring, safe operation, and long-term durability in sanitary environments.

The following are core technology applications that support performance and compliance in food and beverage processing systems:

Core Capabilities for Food & Beverage:

- Valve and door position sensing: Reed switches provide sealed, contactless feedback.

- Temperature and flow monitoring: Hall sensors support analog output.

- Power switching for processing equipment: Relays ensure safe operation.

- Hygienic, corrosion-resistant designs: Ideal for food-grade environments.

- Custom sensor assemblies: Tailored for OEM food processing systems.

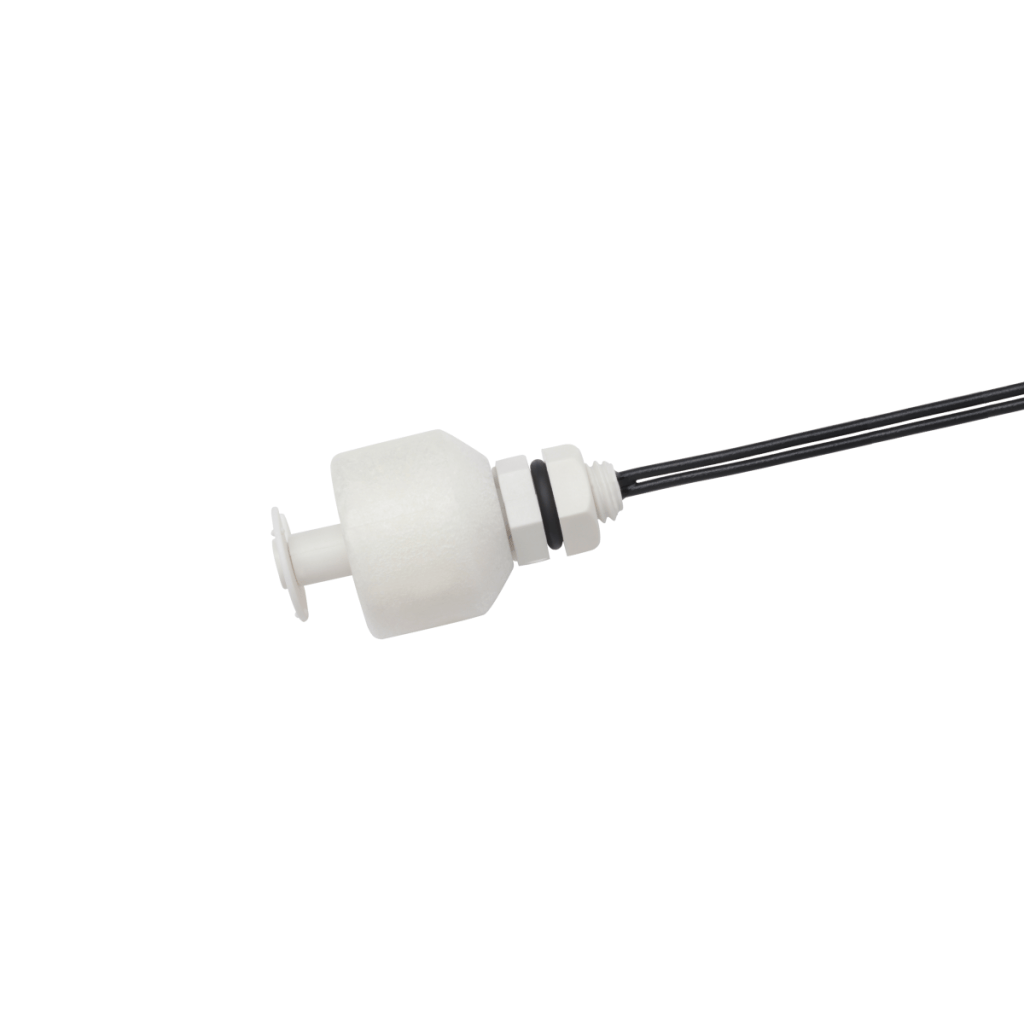

- Float level sensors with FDA approved floats that completely encase magnets

Performance and Protection in Sanitary Settings

Why Partner with Standex Detect for Food and Beverage

Hygiene and reliability are essential in food and beverage processing. Our reed switches, sensors, and relays are designed for clean environments and support automation in packaging, filling, and inspection systems.

- Proven performance in vibration-heavy environments

- Custom solutions for sanitary applications

- Compact sensors for embedded food-grade systems

- Global engineering support and rapid prototyping

Certifications & Compliance

ISO 9001 – Quality management

RoHS – Environmental compliance

IP67-rated designs – Dust and water resistance

UL & CE – Electrical safety

REACH – Chemical safety compliance

FDA – Food safety compliance