Sterile by Design: Reed Switches, Sensors, and Relays That Withstand Heat, Pressure, and Steam

Built for the Heat: Solutions That Survive the Steam

Sterilization equipment such as autoclaves must operate with absolute reliability in high-pressure, high-temperature, and high-humidity environments. These systems are critical to maintaining hygiene and safety in medical, laboratory, and industrial settings. Components must withstand thermal cycling, moisture, and chemical exposure while delivering precise control and feedback. Standex Detect offers sealed, corrosion-resistant reed switches, sensors, and relays engineered for compact integration and long-term durability in sterilization systems.

The following are core technology applications that support safe and reliable operation in sterilizers and autoclaves:

Core Capabilities for Sterilizers/Autoclaves:

- Door lock and seal detection: Reed switches provide sealed, contactless sensing.

- Cycle status monitoring: Hall sensors track mechanical movement and valve positions.

- Power switching for heaters and pumps: Relays ensure safe, isolated operation.

- Signal isolation in control systems: Optocouplers protect sensitive electronics.

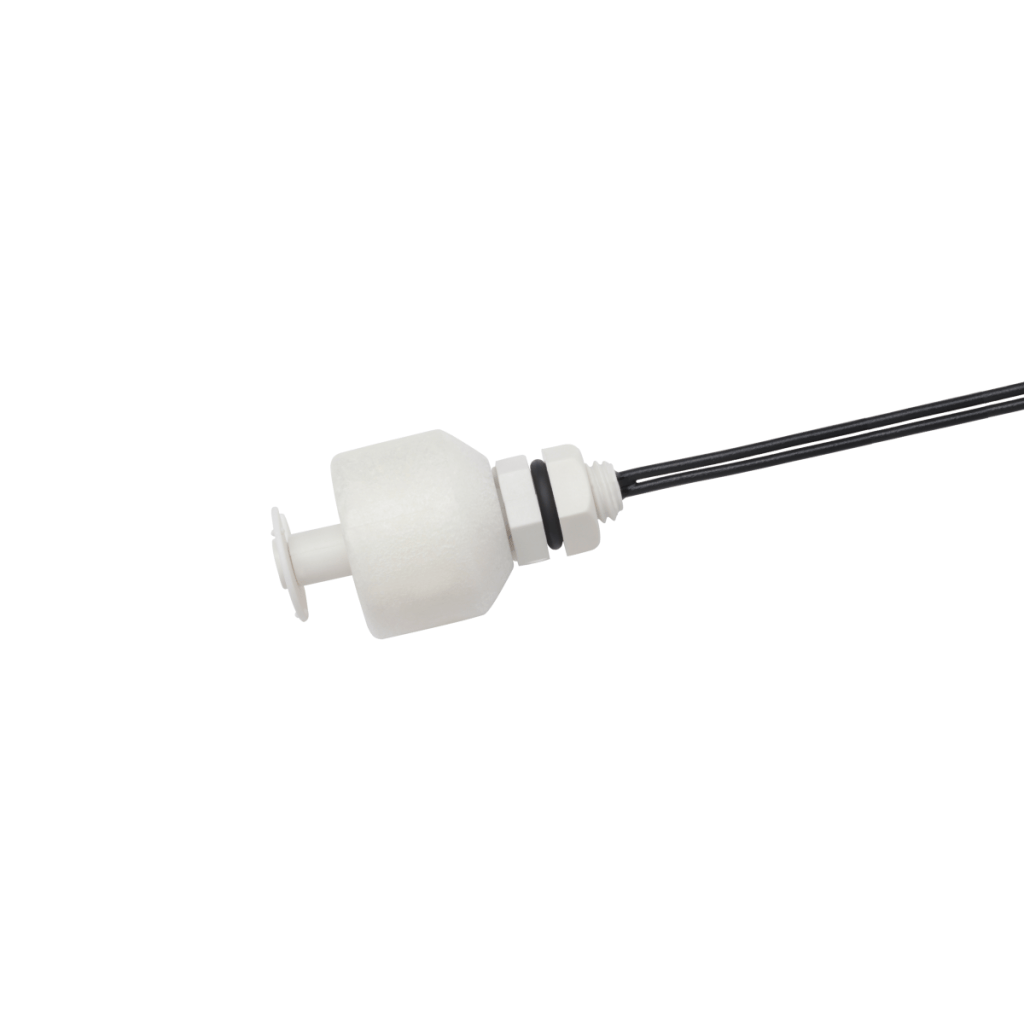

- Custom sensor assemblies: Designed for compact, high-humidity environments.

Performance and Protection in Every Sterilization Cycle

Why Partner with Standex Detect for Sterilizers/Autoclaves

Sterilization equipment requires sensors that withstand heat, pressure, and moisture. Our rugged solutions ensure reliable operation in demanding sanitary environments.

- Proven performance in vibration-heavy environments

- Custom solutions for sterilization systems

- Compact sensors for embedded thermal systems

- Global engineering support and rapid prototyping

Certifications & Compliance

ISO 9001 – Quality management

RoHS – Environmental compliance

IP67-rated designs – Dust and water resistance

UL & CE – Electrical safety

REACH – Chemical safety compliance

Literature

Click on a resource below to download it.