VPD Series Digital Ferrous Metal Proximity Sensor

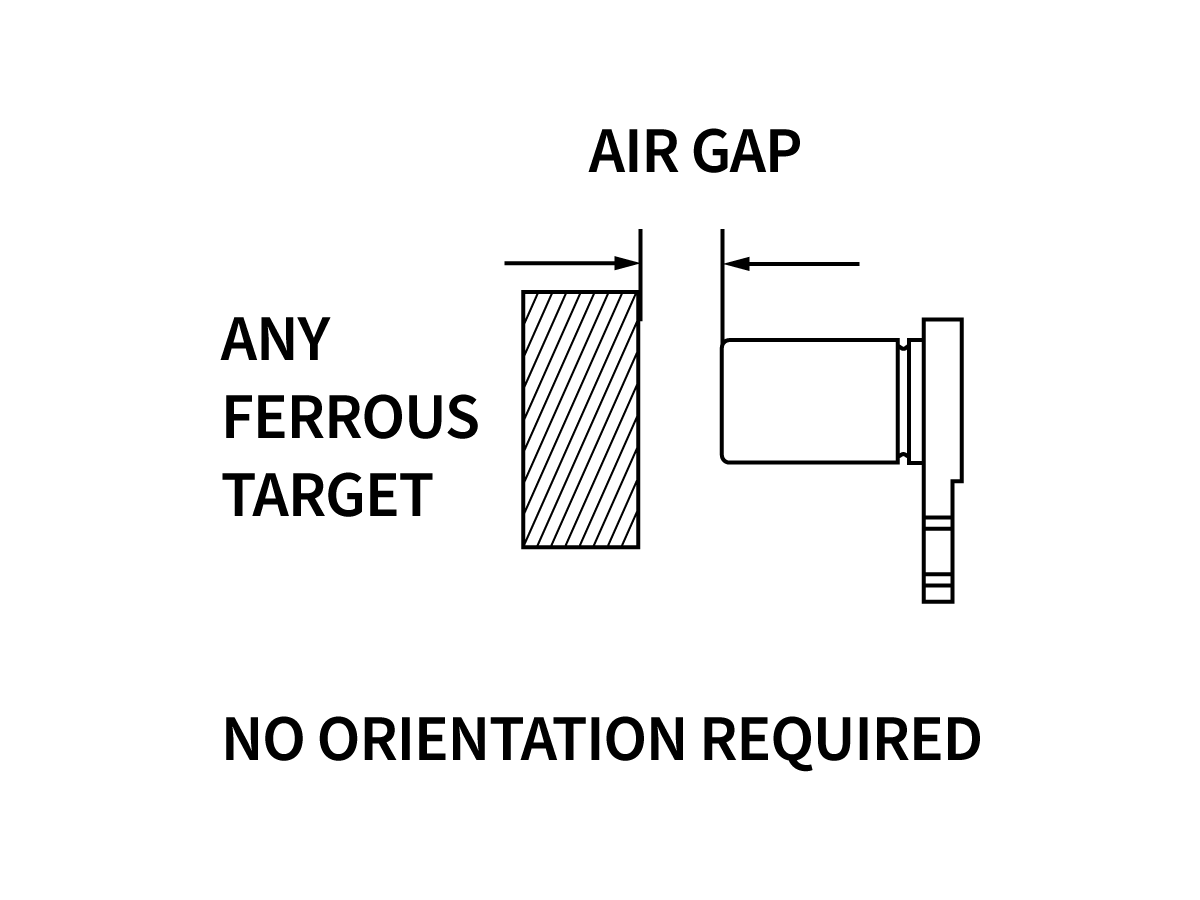

The VPD series offers precise digital sensing of ferrous metal targets with large sensing gap capabilities, delivering consistent performance through air, aluminum, and other non-ferrous materials. Powered by Hall effect technology, these non-contact sensors feature wear-free solid-state designs built to withstand shock, vibration, oils, and coolants.

Whether you’re monitoring steel component alignment in automotive systems or inspecting embedded ferrous targets in manufacturing, the VPD Series delivers dependable, easy-to-install sensing solutions.

Standards and Certifications

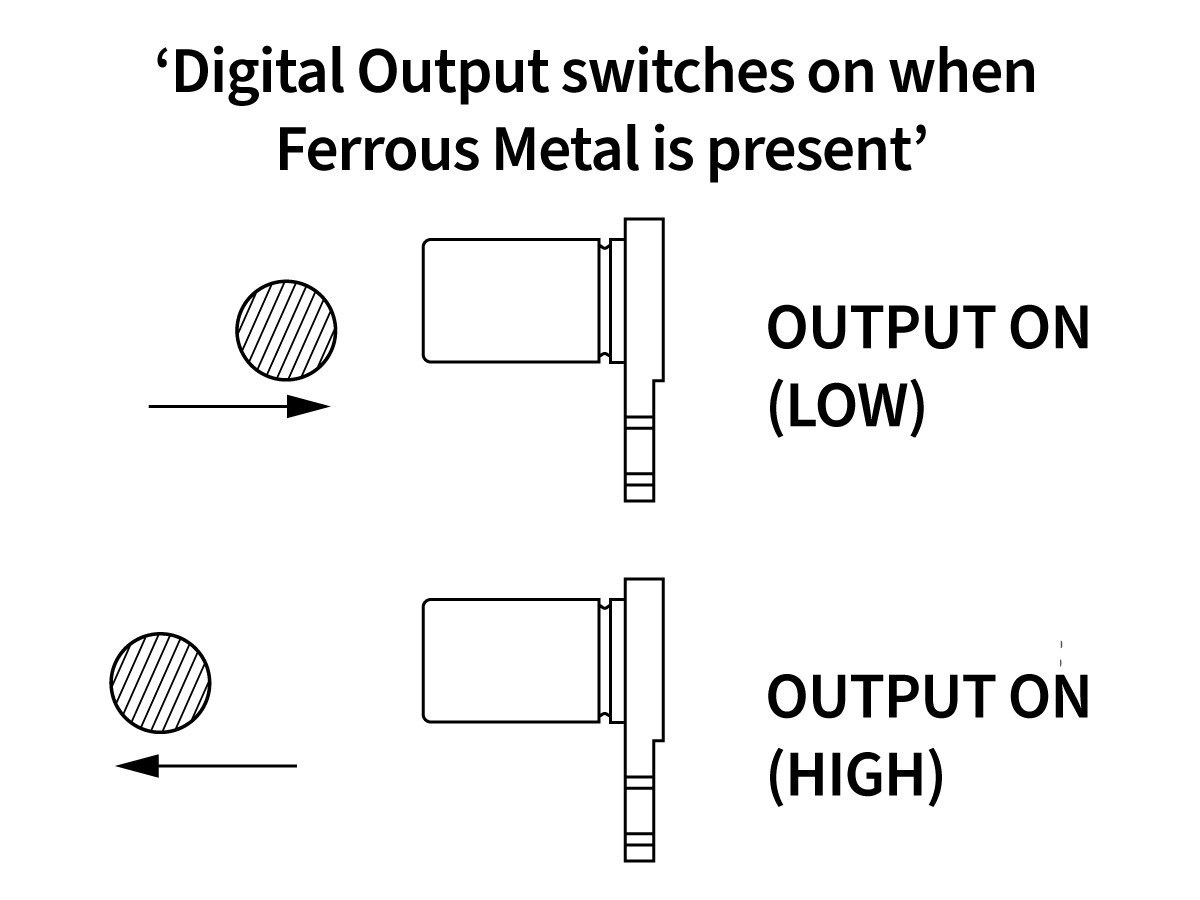

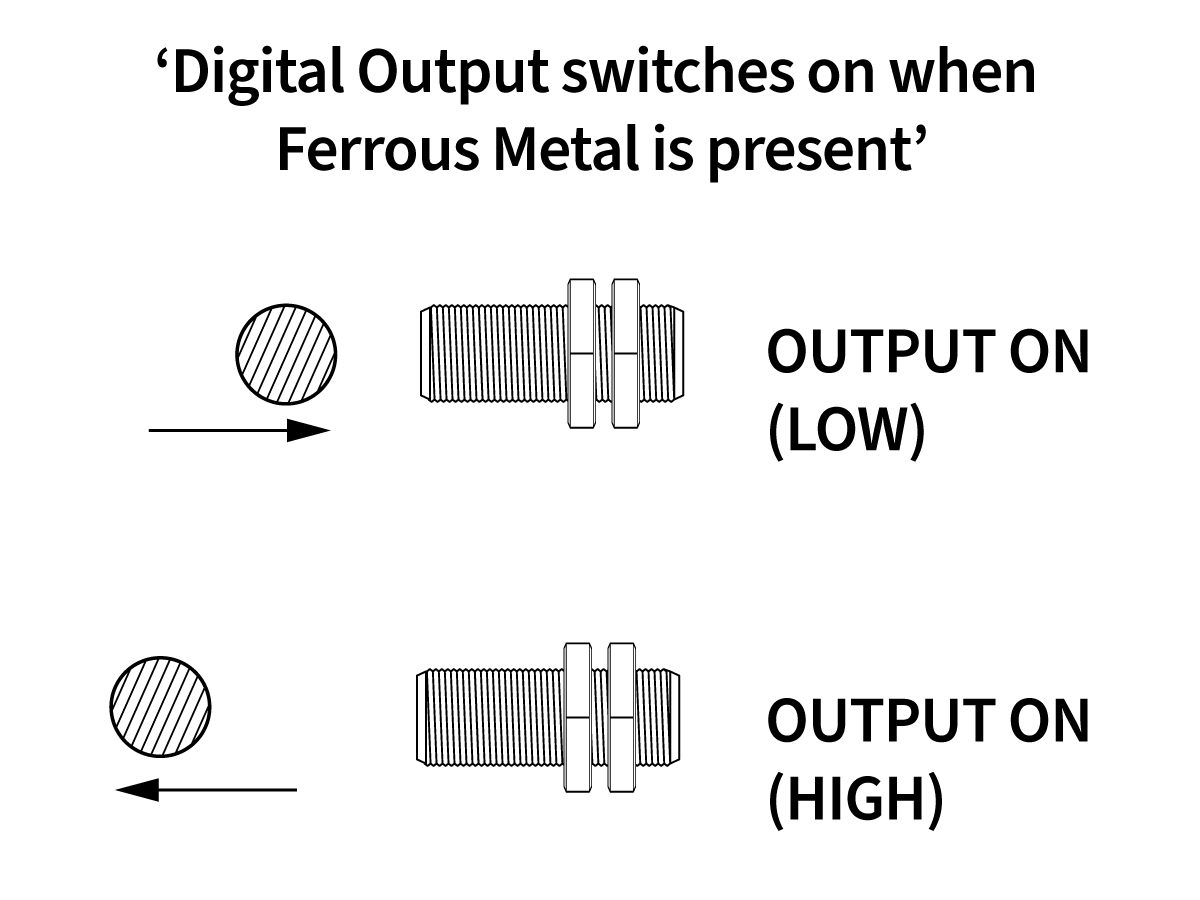

- Digital ON/OFF output for ferrous metal detection

- High durability in harsh industrial and mobile environments

- Stable operation across wide temperature ranges

- Internal hysteresis for bounce-free switching

- Custom programming for repeatable, application-specific detection

- Flexible mounting with threaded and flange options

- Wide range of connector options with free end wires, cable harnesses with connectors, or integrated connectors

| Output Type | Digital 0 to 5V |

| Actuator Material | Ferrous Metal |

| Frequency | 500 Hz |

| Supply Voltage, Vcc | 4.5 ~ 5.5V, 8 ~ 30V |

| Operating Temp. | -40 ~ 110 C |

| Package/Case | Stainless Steel Cylinder, Threaded Aluminum Cylinder, Threaded Plastic Cylinder, Threaded Plastic, Flange Mount |

| Termination Style | Integrated Connector, Cable Harness with Connector, Free End Wire |

- Inspect for steel components below the surface of aluminum extrusions

- Proximity feedback of components in automation equipment

- Monitor position of steel components in engines and transmissions

- Determine alignment between assemblies moving parallel to each other

- Indication of component alignment in agricultural and heavy equipment

- Measuring steel shaft runout

- Counting steel components on conveyor systems

- Position feedback in robotic systems

- Inspecting to verify materials are ferrous

- Detect approaching assemblies before impact