Magnets play a critical role in activating reed switches, with their material, shape, and magnetic properties directly influencing sensor performance. This guide explores various magnet types, such as AlNiCo, rare earth, and hard ferrite, highlighting their specifications, applications, and handling considerations to help engineers select the optimal magnet for reliable and efficient sensor integration.

If there are particular areas you need help with, feel free to skip to any of the following sections:

- Magnet Specifications

- Magnet Materials Information

- AlNiCo Magnets

- Rare Earth Magnets

- Hard Ferrite Magnets

- Magnet Handling

- Magnetization Examples

Magnets and Their Specifications

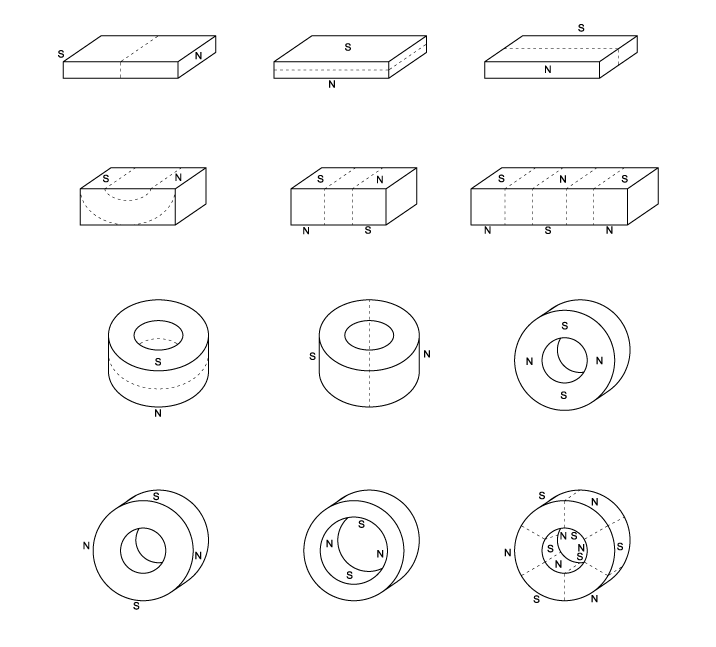

Magnets are available in multiple specifications on the market. Almost all dimensions and geometries can be realized. To activate the Reed switch a magnet (magnet

field) is needed. The different magnet materials have either more positive or negative specifications, depending on the dimension and geometries as well as on the

environment. Most preferred and used forms are cylinders, rectangles, and rings. Depending on the different requirements, magnets can be magnetized in many

different ways (figure #1).

Furthermore, each magnet material has a different magnet force as well as a different flux density. Additionally, to dimension and material, other factors exist that define

the energy of a magnet. These are mounting position, environment and other magnetic field which influence the interaction between reed sensor/switch and magnet. In

applications where a magnet is used to activate a Reed sensor/switch, the environmental temperature needs to be considered (in the application as well as in storage). High temperatures can cause irreversible damage (so-called Curie temperature) and will have heavy impact on the magnetic force and the long-term stability. AlNiCo magnets are best suitable for applications up to 450°C.

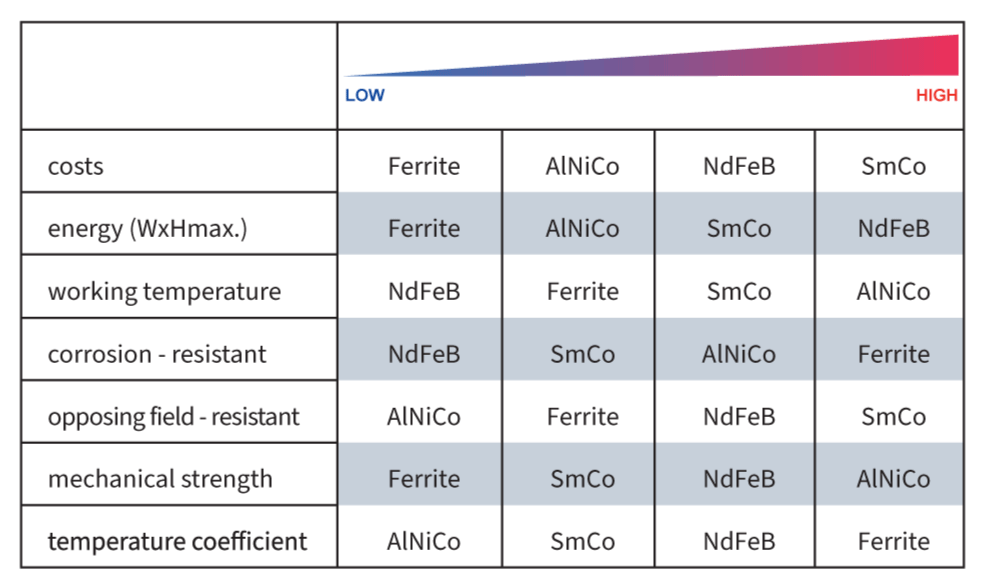

Magnet Materials Information

Magnets have reversible and irreversible demagnetization specifications. Be specifically careful with shock, vibration, strong and close external magnetic fields as well as high temperatures. All these factors influence the magnetic force and the long-term stability in different intensities. Preferably the magnet is mounted on the moving part of the application. Professional tuning of magnet and reed switch can improve the

functionality of the whole sensor-magnet system.

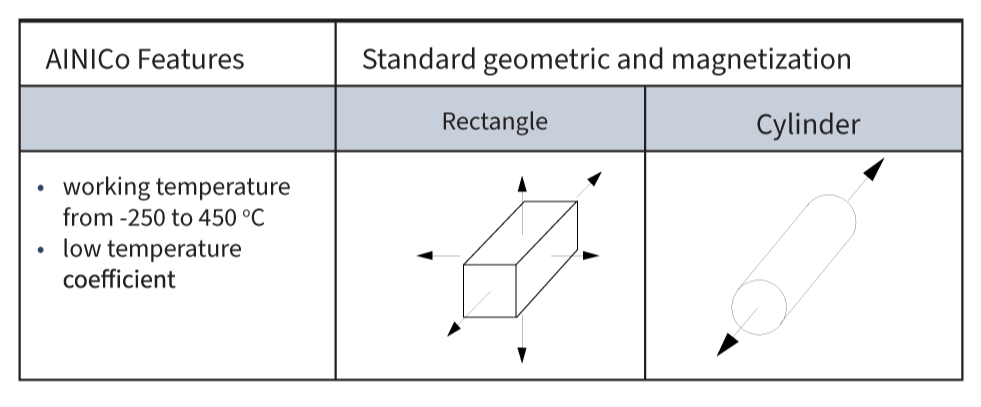

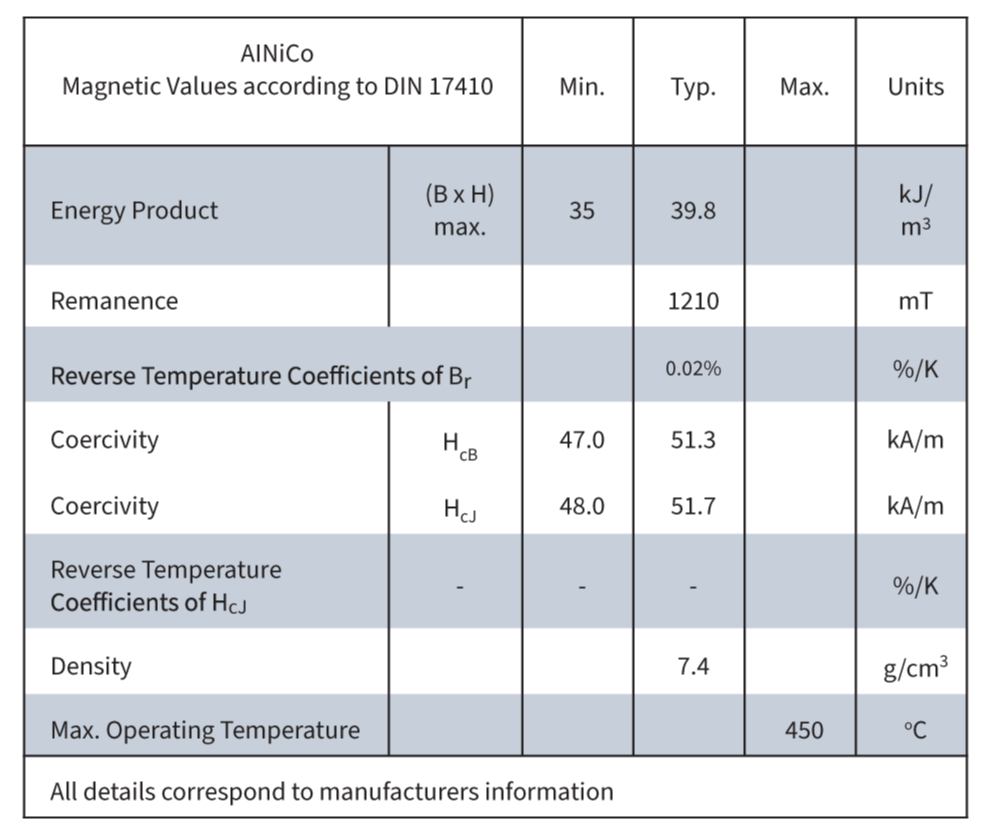

AlNiCo (Aluminum Nickel Cobalt) Magnets

Raw materials for AlNiCo magnets are aluminum nickel, cobalt, iron and titanium. AlNiCo magnets are produced in a sintering – casting procedure. The hard material needs to be processed by grinding to be cost effective. Due to its specifications, the best dimension is a remarkably longer length than its diameter. In combination with Reed sensors / switches we recommend a length / diameter ratio of more than 4. AlNiCo magnets have an excellent temperature stability. Cylindrical AlNiCo magnets can be used with all Standex Detect Reed sensors / switches without any problems.

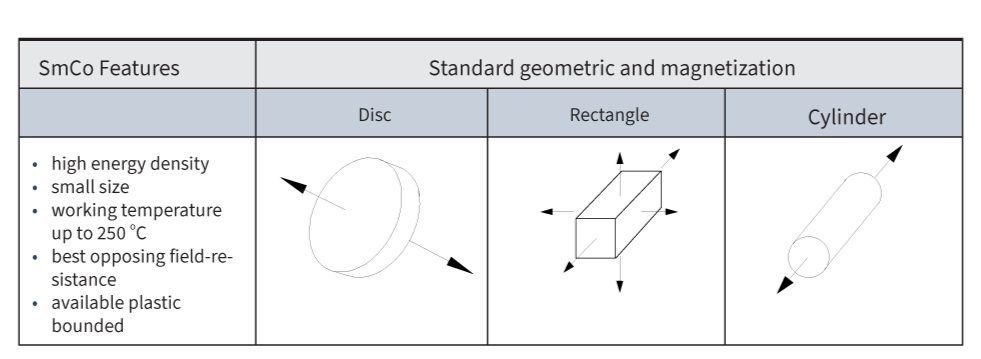

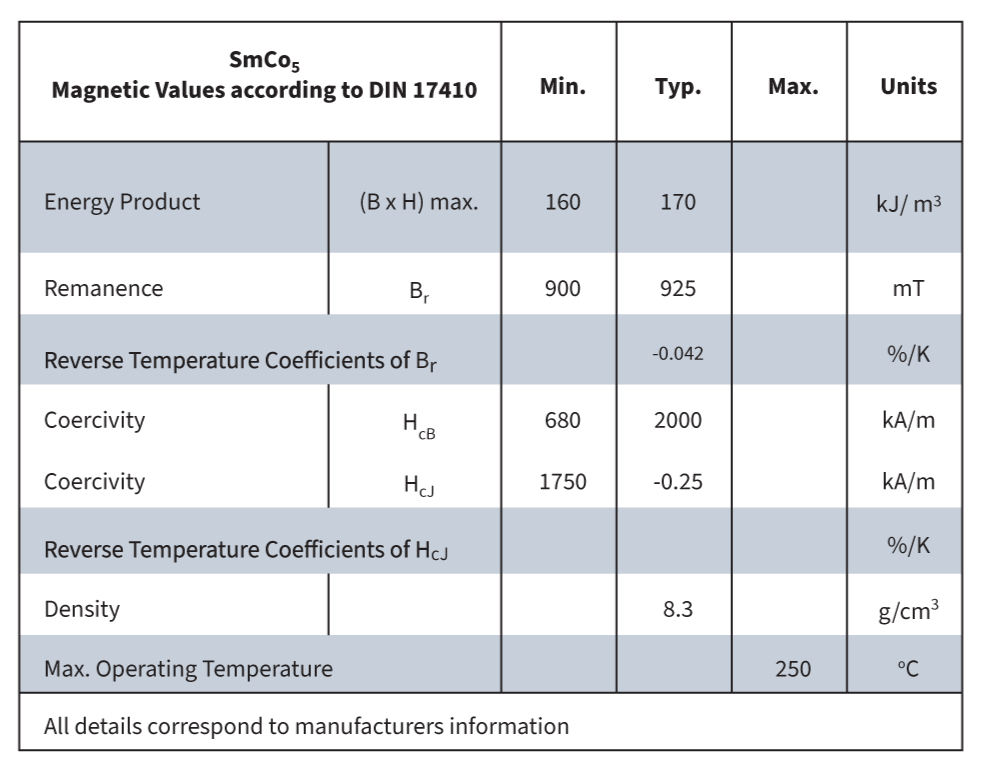

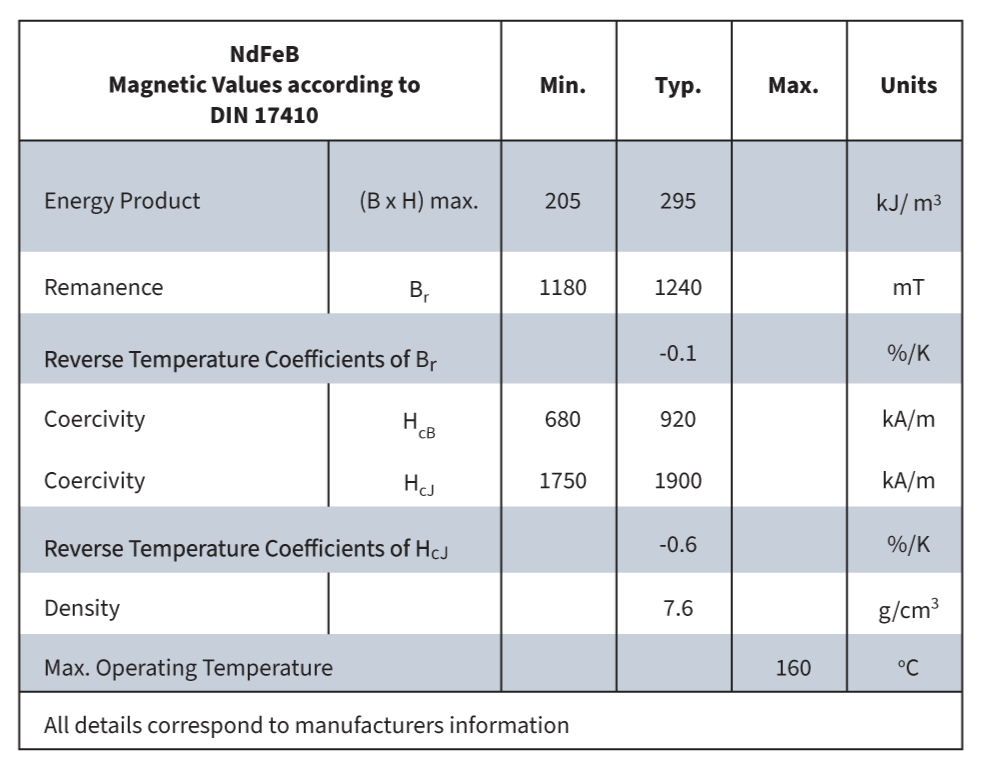

Rare Earth Magnets (NdFeB & SmCo)

Rare earth magnets like SmCo and NdFeB have the highest energy density per volume and weight and also the best demagnetization resistance. Following below, we compare other magnets with the same energy:

- Hard Ferrite = Volumes 6 cm3

- AlNiCo = Volumes 4 cm3

- SmCo = Volumes 1 cm3

- NdFeB = Volumes 0.5 cm3

Both magnets are produced by sintering and can only be processed by grinding, due to the strength and brittle of the material. The temperature range goes up to + 250 °C. Very small magnets can be produced. Disadvantages are the high raw material prices and the limited availability of special alloys.

The supply of different geometry, size and magnetization allow many creative combination of Reed sensor / switch and magnet and help to find the best functionality of the sensor-magnet system for each application.

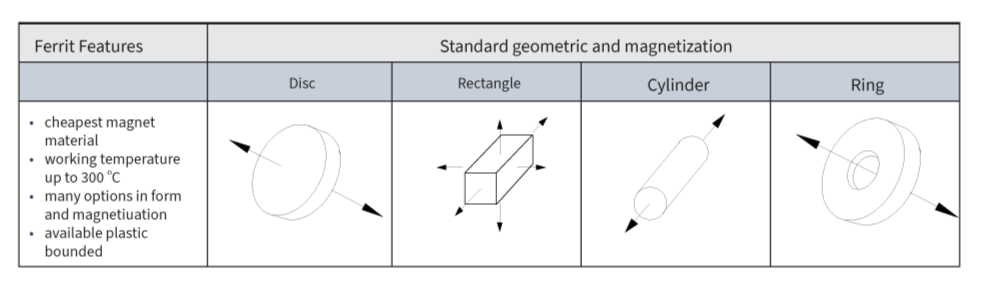

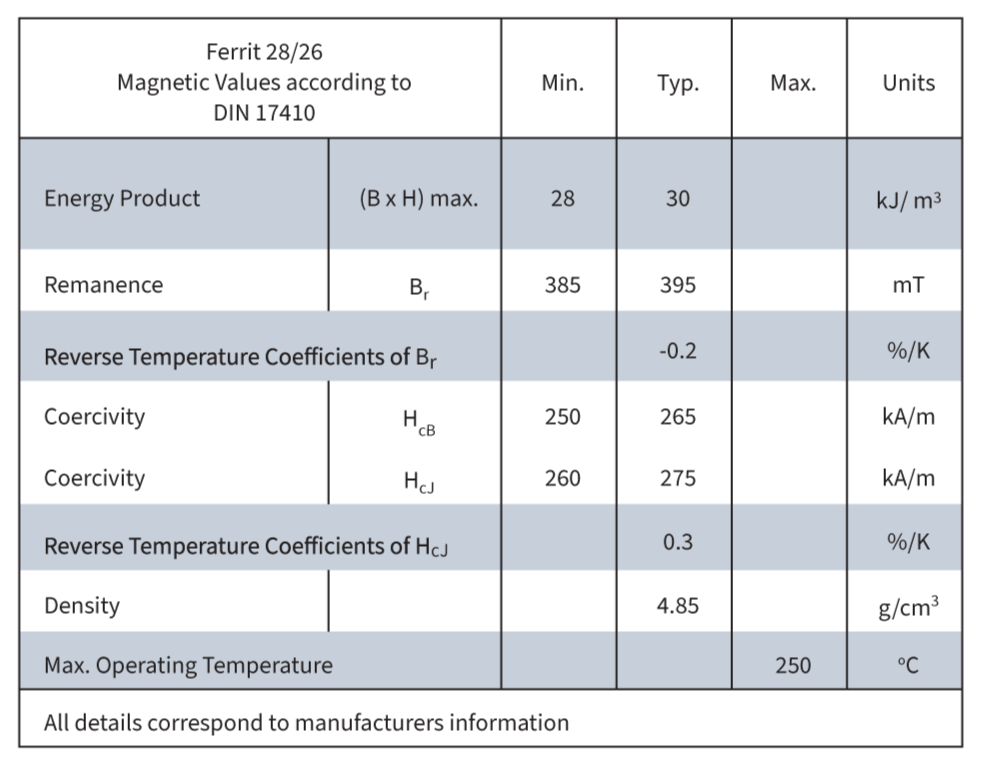

Hard Ferrite Magnets

Hard ferrite magnets are produced with iron oxide and barium or strontium oxide. The raw materials are mixed together and normally pre sintered, to generate the magnetic phase. The pre sintered mixture then gets crushed. The resulting powder gets pressed together (wet or dry) either in a magnetic field (an – isotropic) or without a magnetic field (isotropic) and in the end sintered. Proceedings are only possible by grinding. Due to the low cost of the raw material, hard ferrite magnets are the cheapest magnet type out of the actual supply of magnets. Ferrites have a very good electrical isolation effect and are hard to demagnetize even in strong external magnetic fields. Corrosion tendency is low. Preferred shapes are long and thin but also round forms are easy

to produce. Disadvantages are the high breakability and the low tensile strength. The strength and brittleness of hard ferrites are similar to ceramics. Furthermore the

temperature resistance is limited, and they have only a low energy to volume ratio.

Magnet Handling Guidelines

Magnets, especially high-strength rare-earth types, pose unique safety risks during handling and processing. To prevent injury, equipment damage, and fire hazards, it is essential to follow specific precautions. The guidelines below outline critical safety measures to ensure safe and responsible magnet use in industrial and laboratory environments.

- Risk of Skin Injury

- Strong magnetic forces can cause skin bruises. Maintain a safe distance between magnets and all ferromagnetic materials.

- Splinter Hazard

- High-energy magnet collisions may produce splinters. Always wear protective gloves and safety glasses.

- Fire Risk from Grinding Dust

- Grinding dust from rare-earth magnets is spontaneously flammable. Always grind with water.

- Explosion Risk in EX Environments

- Magnet collisions can cause sparks. Do not handle or process magnets in explosive (EX) environments.

- Electromagnetic Interference

- Strong magnetic fields can disrupt electronic devices and data storage. Keep magnets away from pacemakers, navigation tools, diskettes, and circuit boards.

- Air Cargo Regulations

- Special declarations may be required for air transport of magnets.

- Magnetic Force Reduction

- Radioactivity and joining like poles can weaken magnetic strength.

- Temperature Limits

- Do not exceed the maximum defined operating temperature of the magnet.

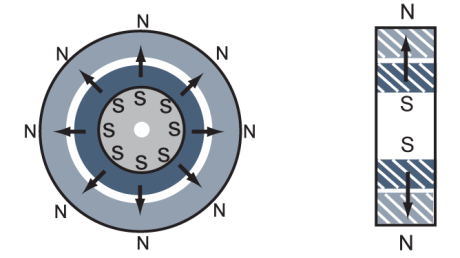

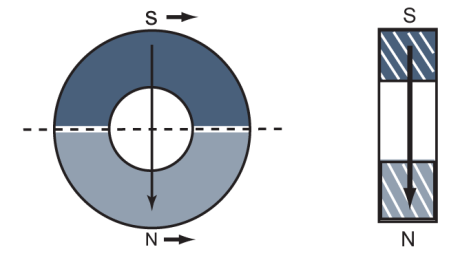

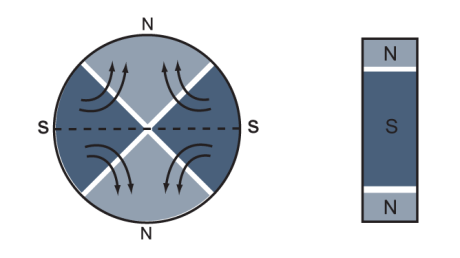

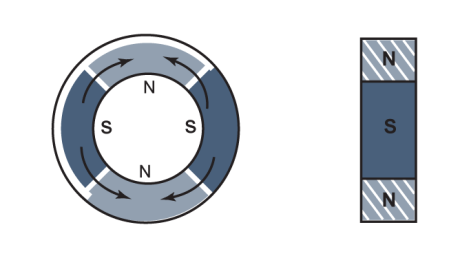

Magnetization Examples

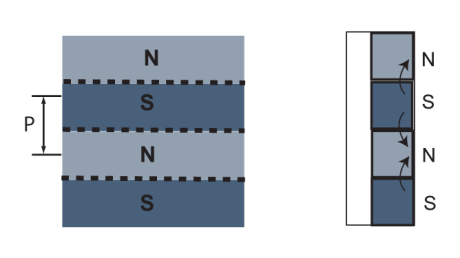

Diagram

Magnetization

Applications

Arrangement

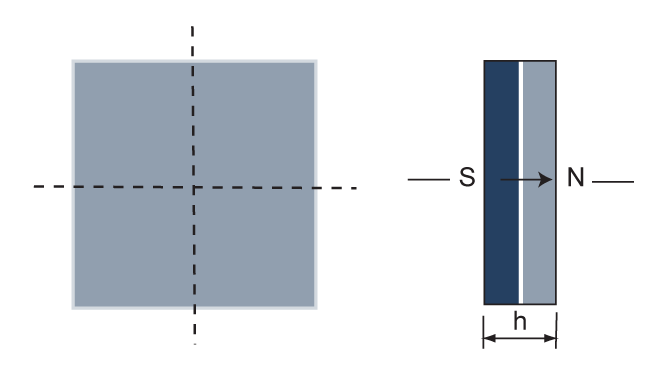

Magnetized in height (preferred orientation)

Motors, magnetic couplings,

ABS-systems, locking systems,

cutter, press cylinder

Isotropic

Anisotropic

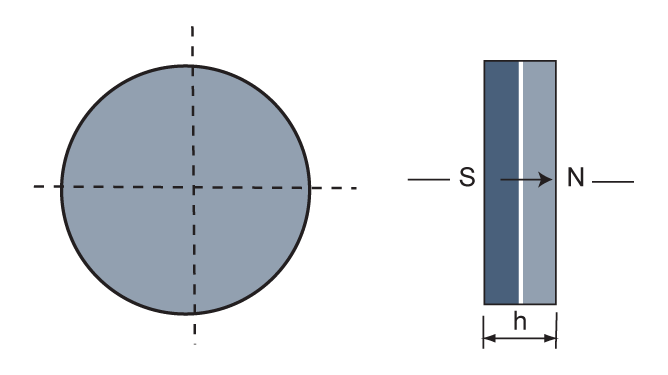

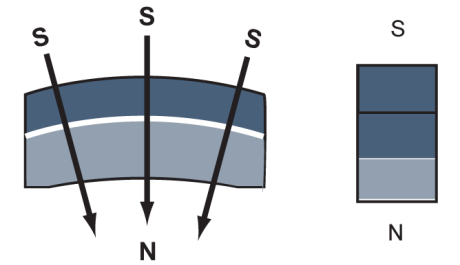

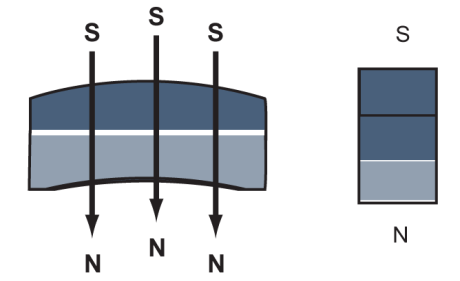

Axial magnetization

Loud-speakers, pot-magnet

systems, holding systems,

magnet switch, protection gas

control

Isotropic

Anisotropic

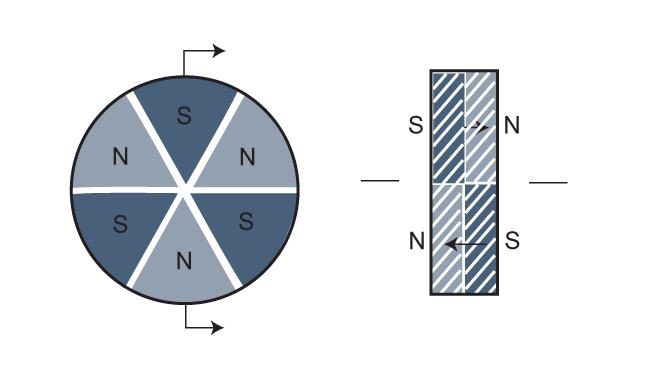

Axial, sector-shaped magnetized,

e.g. 6-pole

Synchronized motors, magnetic

couplings, brakes, Hall

sensors, hard-disc-drive

Isotropic

Anisotropic

Radial magnetization

Lifting magnets, holding systems,

magnet bearings

Isotropic

Anisotropic 1)

Diametric magnetization

Synchronous motors, pumps

Isotropic

Anisotropic 1)

Magnetized on sector shaped

surface, e.g. 6-pole magnet

Magnetic separation, brakes,

holding systems, Hall sensors,

hard-disc-drive

Isotropic

Anisotropic

Pole-oriented

Multi-pole in circumference

magnetized e.g.

4-pole

Dynamos, engines, magnetic

couplings, brakes, Hall sensors,

tachometer

Isotropic

Pole-oriented

Two- or multi pole

magnetized at inside -ø,

e.g. 4-polig

Magnetic couplings, brakes,

motors, Hall sensors, tachometer

Isotropic

Anisotropic

Magnetized on lamellar shaped

surface P = pole pitch

Holding systems, protection

gas control. Hall sensors,

brakes

isotropic

anisotropic

pole-oriented

Radial magnetization

Motors, magnetic couplings

Isotropic

Anisotropic

Diametric magnetization

Motors, magnetic couplings

Isotropic

Anisotropic