Introduction

The Reed switch was first invented by Bell Labs in the late 1930s. However, it was not until the 1940s when it began to find application widely as a sensor and a Reed relay. Here it was used in an assortment of stepping/switching applications, early electronic equipment and test equipment. In the late 1940s Western Electric began using Reed relays in their central office telephone switching stations, where they are still used in some areas today. The Reed switch greatly contributed to the development of telecommunications technology. Over the years several manufacturers have come and gone, some staying longer than they should have, tainting the marketplace with poor quality, and poor reliability. However, most of the manufacturers of Reed switches today produce very high quality and very reliable switches. This has given rise to unprecedented growth.

Today, Reed switch technology is used in all market segments including test and measurement equipment, medical electronics, telecom, automotive, security, appliances, general purpose, etc. Its growth rate is stronger than ever, where the world output cannot stay abreast with demand. As a technology, the Reed switch is unique. Being hermetically sealed, it can exist or be used in almost any environment. Very simple in its structure, it crosses many technologies in its manufacture. Critical to its quality and reliability is its glass to metal hermetic seal, where the glass and metal used must have exact linear thermal coefficients of expansion. Otherwise, cracking and poor seals will result. Whether sputtered or plated, the process of applying the contact material, usually Rhodium or Ruthenium, must be carried out precisely in ultra clean environments similar to semiconductor technology. Like semiconductors, any foreign particles present in the manufacture will give rise to losses, quality and reliability problems.

To meet our customer’s needs, Standex Detect decided to build up their own assembly line. Reed switches are produced since 1968 in England and since 2001 in

Germany.

Over the years, the Reed switch has shrunk in size from approximately 50 mm (2 inches) to 3.9 mm (0.15 inches). These smaller sizes have opened up many more applications particularly in RF and fast time domain requirements.

Reed Switch Features

- Ability to switch up to 10,000 Volts

- Ability to switch currents up to 5 Amps

- Ability to switch or carry as low as 10 nano-Volts without signal loss

- Ability to switch or carry as low as 1 femtoAmp without signal loss

- Ability to switch or carry up to 7 GigaHz with minimal signal loss

- Isolation across the contacts up to 1015 W

- Contact resistance (on resistance) typical 50 milliOhms (mW)

- In its off state it requires no power or circuitry

- Ability to offer a latching feature

- Operate time in the 100 ms to 300 ms range

- Ability to operate over extreme temperature ranges from –55 °C to +200 °C

- Ability to operate in all types of environments including air, water, vacuum, oil, fuels, and dust laden atmospheres

- Ability to withstand shocks up to 200 Gs

- Ability to withstand vibration environments of 50 Hz to 2000 Hz at up to 30 g

- Long life. With no wearing parts, load switching under 5 Volts at 10 mA, will operate well into the billions of operations

- No power consumption, ideal for portable and battery-powered devices

- No switching noise

The Basic Reed Switch

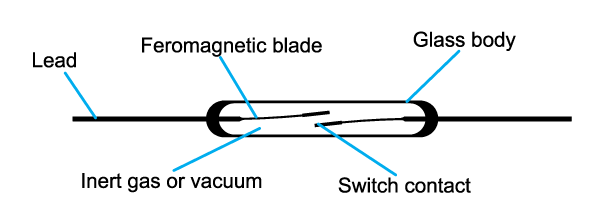

A Reed switch consists of two ferromagnetic blades (generally composed of iron and nickel) hermetically seal powered in a glass capsule (Figure #1). The blades overlap internally in the glass capsule with a gap between them and make contact with each other when in the presence of a suitable magnetic field. The contact area on both blades is plated or sputtered with a very hard metal, usually Rhodium or Ruthenium. These very hard metals give rise to the potential of very long lifetimes if the contacts are not switched with heavy loads. The gas in the capsule usually consists of Nitrogen or some equivalent inert gas.

Some Reed switches, to increase their ability to switch (up to 10 kV) and standoff high voltages, have an internal vacuum. The reed blades act as magnetic flux conductors

when exposed to an external magnetic field from either a permanent magnet or an electromagnetic coil. Poles of opposite polarity are created and the contacts close

when the magnetic force exceeds the spring force of the reed blades. As the external magnetic field is reduced so that the force between the reeds is less than the restoring

force of the reed blades, the contacts open.

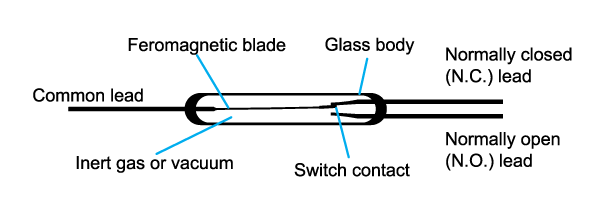

The Reed switch described above is a 1 Form A (normally open (N.O.) or Single Pole Single Throw (SPST) Reed switch. Multiple switch usage in a given configuration is described as 2 Form A (two normally open switches or Double Pole Single Throw (DPST), 3 Form A (three normally open switches), etc. A normally closed (N.C.) switch is described as a 1 Form B. A switch with a common blade, a normally open blade and a normally closed blade (Figure #2) is described as a 1 Form C (single pole double throw (SPDT).

The common blade (or armature blade), the only moving Reed blade, is connected to the normally closed blade in the absence of a magnetic field. When a magnetic field of

sufficient strength is present, the common blade swings over to the normally open blade. The normally open and normally closed blades always remain stationary.

All three Reed blades are ferromagnetic; however, the contact area of the normally closed contact is a non-magnetic metal which has been welded to the ferromagnetic blade. When exposed to a magnetic field, both of the fixed reeds assume the same polarity which is opposite to that of the armature. The paddle then moves over to the normally

open blade.

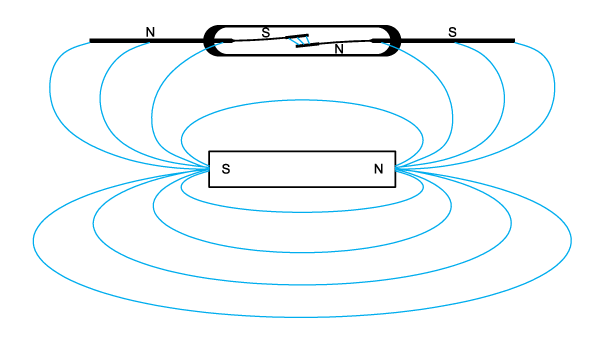

Figure 3 shows the general function of a Reed switch with the use of a permanent magnet.

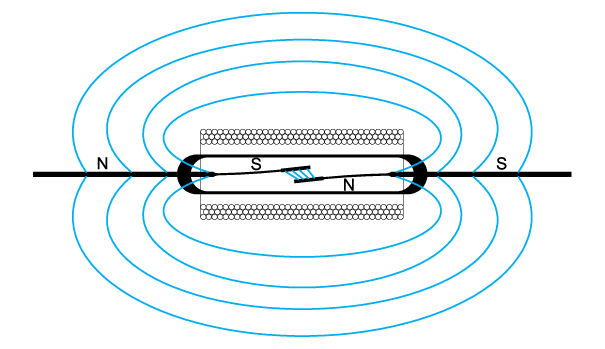

The use of a coil wound with copper insulated wire. See Figure 4.

When a permanent magnet, as shown, is brought into the proximity of a Reed switch the individual reeds become magnetized with the attractive magnetic polarity as shown. When the external magnetic field becomes strong enough the magnetic force of attraction closes the blades. The Reed blades are annealed and processed to remove any magnetic retentively. When the magnetic field is withdrawn the magnetic field on the Reed blades also dissipates. If any residual magnetism existed on the Reed blades, it would affect the behavior of opening and closing. Proper processing and proper annealing clearly are important steps in their manufacturing.