Precision in Motion: Empowering Industrial & Automation Equipment with Advanced Reed Switches, Sensors, and Relays

Built for Industry: Custom Reed Switches, Sensors, and Relays for Harsh Environments

In today’s rapidly evolving industrial environment, automation and intelligent systems are transforming how equipment operates. Manufacturers and system integrators face growing demands for efficiency, reliability, and safety, especially in high-cycle, vibration-prone, and harsh conditions typical of industrial and automation equipment.

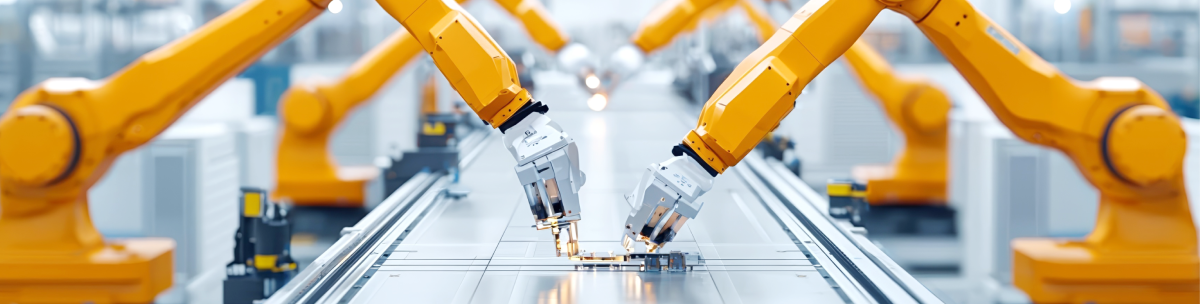

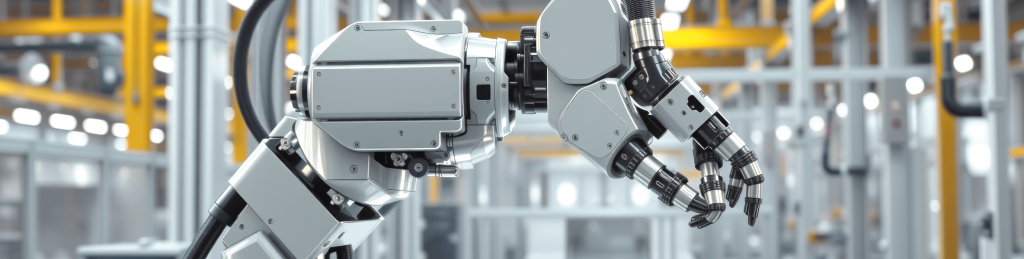

Standex Detect delivers robust reed switches, sensors, and relays engineered to meet the unique challenges of industrial automation. Our components are designed to integrate seamlessly into automated systems, enhancing performance, enabling predictive maintenance, and ensuring operational safety across a wide range of industrial equipment, from robotic arms and conveyor systems to fluid control and machine monitoring.

With decades of expertise and a focus on innovation, our Technology Portfolio for Industrial & Automation Equipment supports OEMs and equipment manufacturers in building smarter, more resilient systems.

Technology Portfolio for Manufacturing

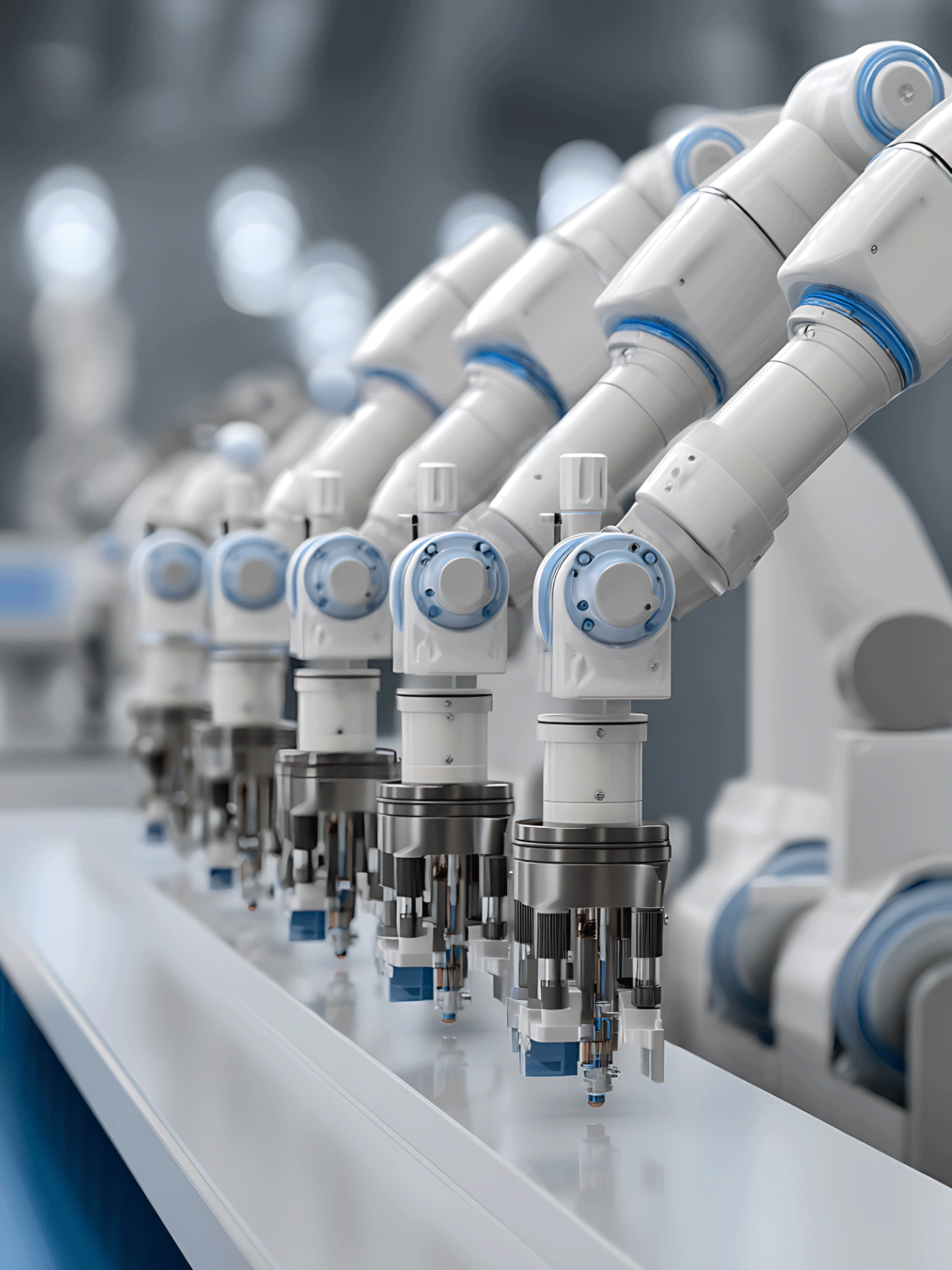

- Reed Switches: Hermetically sealed for durability in rugged environments. Ideal for use in safety interlocks, fluid level detection, and position sensing within industrial machinery and automation systems.

- Reed Sensors: Contactless and low-power, these sensors deliver reliable position and proximity detection in automated equipment such as packaging machines, conveyors, and robotic systems.

- Hall Effect Sensors: Solid-state sensors with analog or digital output for speed, angle, and position measurement, perfect for motor control, gear monitoring, and robotic motion tracking.

- Reed Relays: Compact and efficient, offering high-voltage isolation and low contact resistance. Used in PLCs, industrial control panels, and automated test systems for signal switching.

- Optocouplers: Provide electrical isolation and EMI protection in high-voltage control systems, ensuring safe and accurate signal transmission in noisy industrial environments.

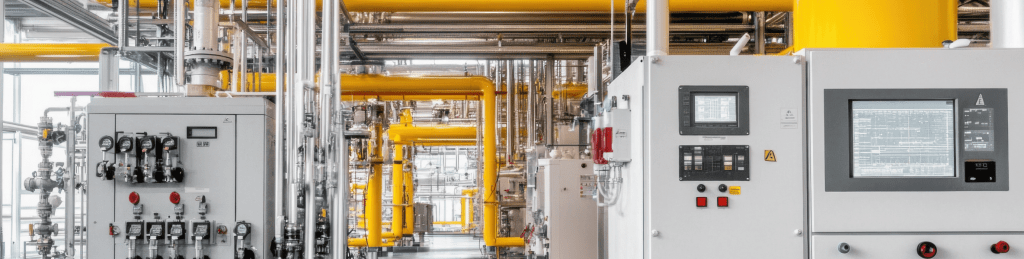

- Fluid Level Sensors: Available in reed, Hall, and capacitive types. Monitor coolant, lubricant, and chemical levels in tanks and reservoirs across automated manufacturing and processing equipment.

- Gear Tooth Sensors: Detect speed, direction, and rotation of shafts and gears, critical for monitoring conveyor belts, robotic joints, and rotating machinery in automated production lines.

Automation in Action: Enabling Scalable, Connected Manufacturing

Engineering Partner in Industrial Automation Innovation

At Standex Detect, we go beyond supplying components, we become an integral part of your engineering team. Through our Innovate | Consult | Engineer | Deliver approach, we collaborate with OEMs and Tier 1 suppliers in the industrial automation space to co-engineer precision reed switches, sensors, and relays that drive smarter, safer, and more efficient equipment performance.

Our approach is built on four foundational pillars that guide every engagement:

- Innovate: Create forward-thinking concepts that address emerging challenges in Industry 4.0, predictive maintenance, and digital transformation of industrial equipment.

- Consult: Engage in open dialogue and technical partnership to understand your unique requirements, becoming a trusted extension of your engineering and automation teams.

- Engineer: Develop tangible, effective solutions through deep technical collaboration and application expertise in factory automation, robotics, and industrial control systems.

- Deliver: Ensure customer satisfaction with solutions that meet stringent performance, quality, and delivery standards, keeping your automation systems and industrial equipment running reliably.

Whether you’re enhancing a single machine or scaling across global production facilities, we bring the agility, customization, and global support needed to help you succeed in the industrial automation landscape.

What Sets Us Apart

- Engineer-to-Engineer Collaboration: We work directly with your technical teams to co-develop sensing and switching solutions tailored to your automation platforms.

- Vertically Integrated Manufacturing: From Reed switches, sensors, and relays we manage the entire process to ensure quality, speed, and consistency.

- Agile Global Supply Chain: With 18 sites across 3 continents, we provide local support, redundancy, and rapid response to evolving industrial demands.

- Custom + Standard Solutions: Whether you need off-the-shelf components or fully customized assemblies, we deliver both with precision and speed.

Why Industrial Equipment OEMs Choose Us

- Custom Engineering: From discrete sensors and relays to integrated assemblies, tailored for factory automation, robotics, and industrial control systems.

- Agility & Speed: Fast response to design changes, equipment upgrades, and evolving automation standards—supporting lean and agile industrial environments.

- Reliability: Components tested for vibration, temperature extremes, and high-cycle operation in demanding industrial settings.

- Scalability: From pilot systems to global equipment deployments, our solutions scale with your automation strategy and manufacturing footprint.

- Innovation: Smart sensing, miniaturization, and ruggedized designs for Industry 4.0, predictive maintenance, and next-generation industrial platforms.

Certified, Reliable, and Customizable Components for Every Stage of Production

Certifications & Compliance

We adhere to globally recognized standards to ensure the safety, reliability, and performance of our reed switches, sensors, and relays across a wide range of industrial and automation environments:

General Manufacturing:

ISO 9001:2015 – Quality Management System

ISO 14001:2015 – Environmental Management System

REACH & RoHS – Compliance with hazardous substance and environmental regulations

CE Marking – Conformity with EU safety, health, and environmental protection standards

Factory Automation:

UL Certifications – For reed switches, sensors, and relays used in industrial control systems

IP67/IP68 Ratings – Environmental protection for components in rugged automation environments

Process Controls:

ATEX & IECEx – Certified components for use in explosive or hazardous industrial zones

Hazardous Locations & ATEX:

DIN EN ISO/IEC 80079-34 – Quality systems for explosive atmospheres

ATEX & IECEx – Explosion-proof and intrinsically safe component certifications

Whitepaper

Advancing Industrial Automation with Reed Switches and Sensors

As industrial automation and robotics rapidly evolve, manufacturers face increasing demands for components that are reliable, durable, and capable of operating in harsh environments, without compromising performance or cost-efficiency.

Standex Detect addresses these needs with a broad portfolio of reed switches, relays, and sensors that offer high reliability, long operational life, and resistance to shock, vibration, and extreme temperatures. These components are hermetically sealed, require no external power, and are ideal for switching low-level signals and high-voltage loads in industrial settings.