Reed relays integrate reed switches with an electromagnetic coil to deliver precise, durable, and long-life switching. With advantages like high insulation resistance, low contact resistance, and billions of operations, they excel in demanding applications from EVs to medical and test equipment.

“A reed relay application uses an electromagnet to control one or more reed switches. Reed relays are the answer to all of the other switching technologies that simply do not meet low-level switching requirements.”

If there are particular areas you need help with, feel free to skip to any of the following sections:

- Introduction

- What is a Reed Relay?

- How Does a Reed Relay Work?

- Features of a Reed Relay

- Reed Relay Advantages

- Where are Reed Relays Used?

- Conclusion

- Additional Resources

Introduction

A reed switch is an electromagnetic switch that operates using an applied magnetic field. Therefore, a magnet controls the flow of electricity in the circuit. A small glass envelope housing two or more ferrous reeds make up the switching mechanism. So, the reed switches open or close in the presence of a magnetic field. The simple design and function of reed switches offer a lot of room for innovation and different uses. Reed switches used in a reed relay application is just one way of innovating with reed technology.

What is a Reed Relay?

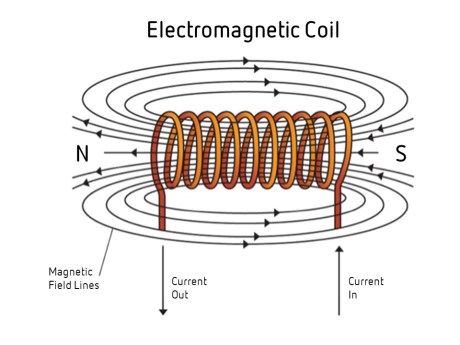

A reed relay is a type of relay that uses an electromagnetic coil to operate one or up to eight reed switches. The reed switch or switches are typically inside the relay’s coil. Insulated copper wire either wound around a bobbin or self-contained makes up the coil.

How Does a Reed Relay Work?

The most basic reed relay operates with a few simple steps. First and foremost, the relays’ electromagnetic coil generates current when voltage is applied. Next, the coil’s current produces a magnetic field that closes the reed switch contacts. Finally, removing the voltage from the coil opens the switch contacts.

Furthermore, reed relays can work in far more advanced ways. For example, an RF reed relay application is designed to switch high frequency signals. Placing a coaxial shield around the reed switch or switches allows the relay to switch signals up to 7 GHz. For more reed relay application examples, jump to the section: Where are Reed Relays Used?

Features of a Reed Relay

Moreover, some reed relay features can’t be met by semiconductor and electromechanical relays. For example, lifetime is one feature that stands out. A result of no wearing parts within the internal reed switch, reed relays can switch billions of low-level operations. Therefore, like semiconductors, reed relays will far outlast electromechanical relays.

Most importantly, no relay technology can switch zero voltage and current like reed relays do! And, semiconductor relays have relatively high capacitance and leakage current when compared with reed technology. Similarly, reed relays offer a lot more features and advantages over other relays. Check out some of these features in the below list.

Reed Relay Advantages

Reed Relays offer a wide range of unique switching advantages, including:

- Hermetically sealed from dust, debris, or corrosion

- Reliable in hazardous locations for intrinsic safety

- Billions of lifetime switching (load dependent)

- Up to 8 reed switches in a single relay

- Below 50mOhms contact resistance

- High insulation resistance >10^15 Ohms

- Switching up to 10,000 Volts’

- Carry currents up to 5 Amps

- Operate times range from 500 microseconds to 3 milliseconds

- Very low signal switching in nanovolts range

- High frequency switching up to 7 Gigahertz

- Tested according to automotive standard AEC-Q200 (KT series)

- Comply with UL, CSA, VDE, ATEX, IECEx and more (select series)

Where are Reed Relays Used?

With so many features, the most demanding applications and emerging markets use reed relays. For instance, below is a list of some common reed relay application examples.

Applications

- Battery management and conditioning systems in cars, especially in electric and hybrid

- High voltage insulation in renewable energy, photovoltaic, solar, and power distribution systems

- Voltage isolation in medical equipment such as surgical generators and automated external defibrillators

- High density matrices in test equipment, integrated circuit, and precision testers, as well as multiplexers

- Intrinsic safety in mining, oil and gas production, and geothermal and seismic instruments

Conclusion

In short, reed relays meet the low-level switching needs that all other relay types simply do not. In other words, reed relays offer high voltage and high RF switching. Likewise, the reed relay can switch very low voltages and currents over its long lifetime. In conclusion, reed relays stand up to the high demands of modern electronics very well, when properly designed in.

Standex Detect designs custom-made reed relays in a large array of packages that offer special features. Contact our relay experts to get started on a design that meets your specific needs.

Additional Resources

Take a look at our reed relay product line brochure for more information on the range of relays offered by Standex Detect.