Burn-in testers challenge every aspect of relay performance. At low-voltage, accuracy can be compromised by resistance drift, parasitics, and contamination. At high-voltage, isolation and leakage risks threaten both safety and data integrity. Across both domains, long-duration thermal stress demands endurance.

If there are particular areas you need help with, feel free to skip to any of the following sections:

- High Voltage Reed Relays for Burn-In Testing

- Requirements in Burn-In Test Switching

- Low-Voltage Challenges and Solutions

- High-Voltage Challenges and Solutions

- Design and Selection Guidelines

- Summary

High-Voltage Reed Relays for Burn-In Testing

Burn-in and life test systems are essential tools in semiconductor and electronics reliability testing. Devices under test (DUTs) such as memory ICs (DRAM, Flash), processors (CPUs, GPUs), discrete power semiconductors (MOSFETs, IGBTs), and wide-bandgap devices (SiC and GaN modules) are operated under elevated stress conditions for extended periods to expose early-life failures and verify long-term performance.

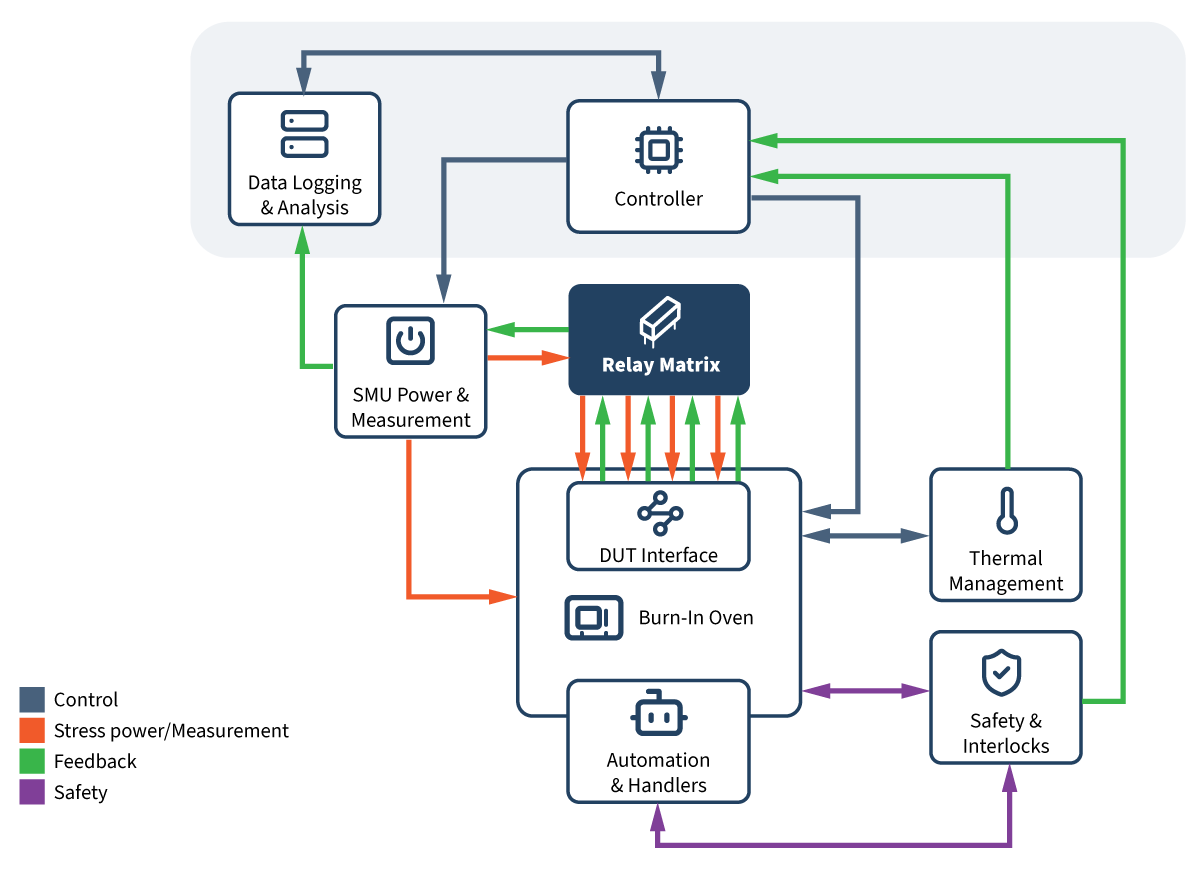

A critical component of these systems is the switching element that connects, isolates, or routes signals and voltages to each DUT. Reliability, signal fidelity, and high-voltage isolation are non-negotiable.

Depending on the application, burn-in testers may require low-voltage precision switching up to ~200 V, which is typical for ICs and signal measurements, or high-voltage stress testing up to ~3 kV, used mainly for power semiconductors such as MOSFETs, IGBTs, and SiC/GaN devices). In some modular systems both domains can be present, though most burn-in equipment is optimized for one or the other.

Reed relays are widely adopted in this space due to their unique combination of:

- Hermetically sealed contacts for stable, contamination-free switching

- Very low leakage and high insulation resistance for essential for parametric accuracy

- Compact form factors with long mechanical/electrical lifetimes

- Broad range of options covering both precision and high-voltage requirements

Check out the full list

of Standex’s testing

and certifications:

of Standex’s testing

and certifications:

- AEC-Q200

- IEC 60810-4

- IEC 60601-1

- IEC 62109-1/2

- IEC 60664-1

- ISO 6469-3

- IEC 60255-27

- UL Listed

- RohS, REACH

Requirements in Burn-In Test Switching

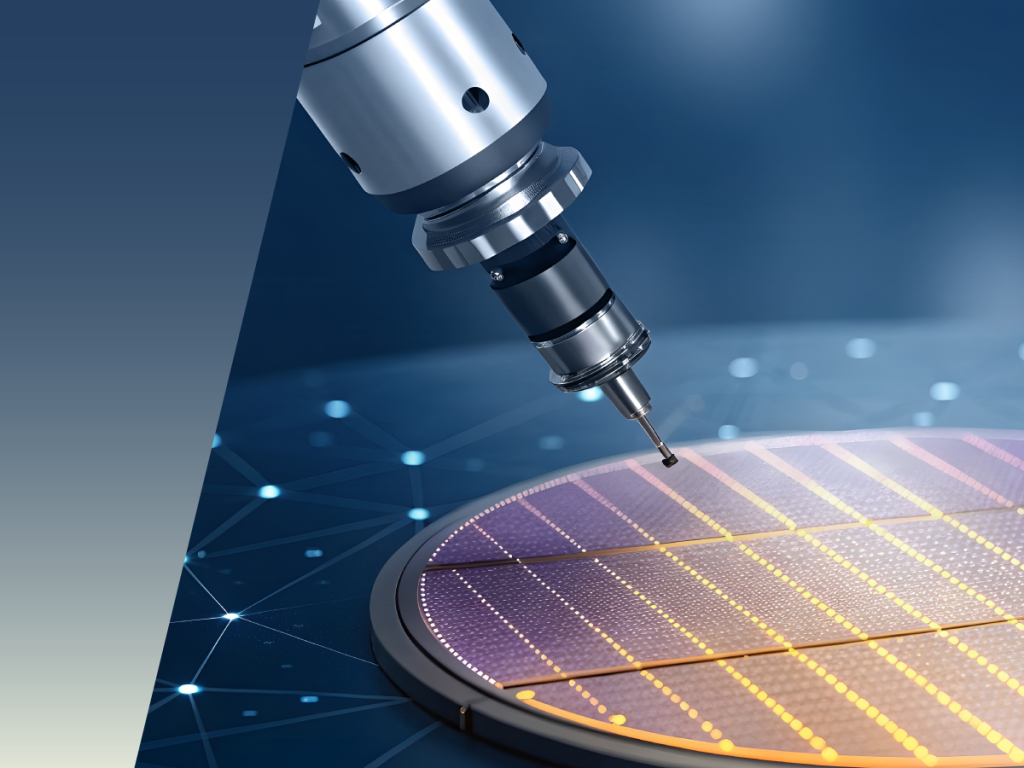

Burn-in systems place heavy demands on switching components. On the low-voltage side (below 200V) engineers must preserve signal integrity across thousands of DUT channels. Even small shifts in contact resistance, thermal EMF, or parasitics can distort measurements. Reed relays counter these issues with stable, low-resistance contacts, very low capacitance and inductance, and hermetically sealed construction that prevents contamination.

At the high-voltage end (above 1kV), the challenge shifts to safety and isolation. Developers must prevent dielectric breakdown, arc-over, and leakage that can corrupt results. High-voltage reed relays address this with compact glass envelopes, high insulation resistance, and well-defined creepage and clearance that simplify PCB design.

Operational stresses add further complexity. Burn-in test runs can last for days, requiring millions of reliable operations in elevated temperatures. Reed relays meet these demands with robust coils, consistent timing, and sealed contacts that ensure long-term stability.

By combining low-voltage precision with high-voltage robustness, reed relays provide a dependable switching technology that simplifies system design and improves

test reliability.

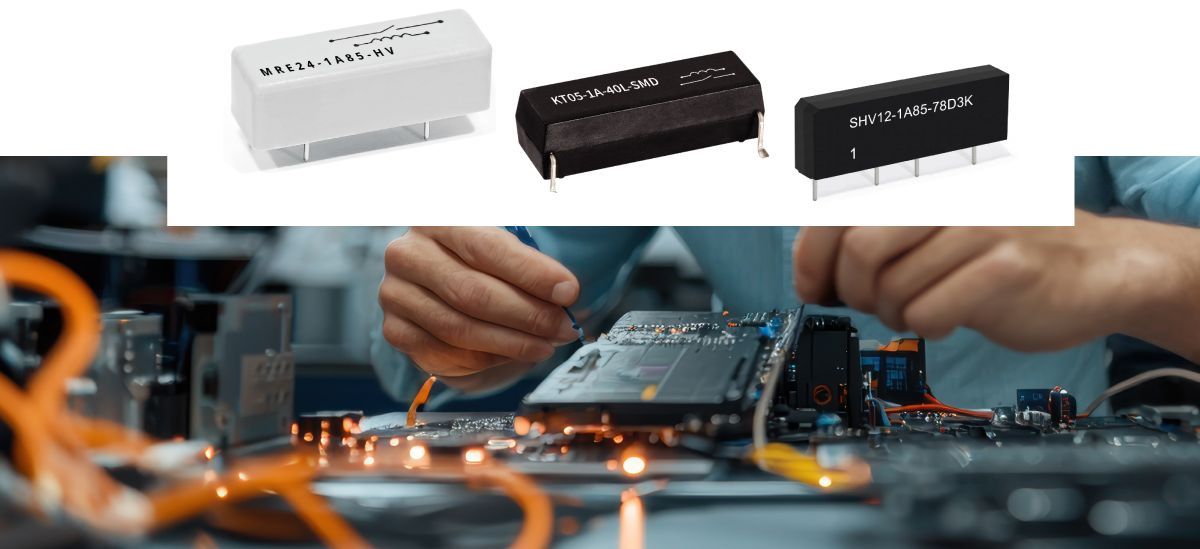

Compact Low-Voltage Switching THT and SMD Series

Low-Voltage Switching Challenges and Solutions

Switching Challenges

- Contact resistance drift can distort parametric measurements.

- Thermal EMF generated at the contact can mask tiny voltage shifts.

- Parasitic capacitance and inductance can corrupt high-sensitivity signals.

Reed Relay Solutions

- Stable, low-resistance contacts preserve measurement integrity over millions of cycles.

- Low thermal EMF avoids spurious voltage generation in precision testing.

- Low parasitic design ensures signal fidelity in dense switching matrices.

- Hermetic sealing prevents contamination that would otherwise degrade contacts.

High-Voltage Switching Challenges and Solutions

Switching Challenges

- Risk of dielectric breakdown, arc-over, or corona effects under continuous stress.

- Leakage currents across the switch path can cause false measurements.

- Large spacing requirements can limit board density.

Reed Relay Solutions

- Compact glass-envelope construction delivers high dielectric strength in small footprints.

- Extremely high insulation resistance minimizes leakage currents.

- Defined creepage and clearance simplify PCB design while ensuring safety margins.

Design and Selection Guidelines

When integrating switching technology into burn-in test equipment, engineers must carefully balance the need for high channel density with the spacing and insulation requirements of high-voltage operation. PCB layout and wiring demand particular attention, especially in circuits where creepage and clearance must be maintained. The compact glass body and proven insulation of reed relays make it possible to achieve kilovolt isolation ratings even in tightly spaced relay matrices. For sensitive low-voltage signal paths, shielded or coaxial relay options are available to minimize magnetic coupling, crosstalk, and stray capacitance.

Reliability remains the defining performance metric in burn-in test systems. Failures in the switching matrix not only compromise measurement accuracy but can also waste days of testing time and occupy valuable equipment capacity. Reed relays have a well-documented record of delivering millions of operations, supported by predictable wear-out mechanisms that allow engineers to apply appropriate derating. Their hermetically sealed contacts resist contamination in the elevated-temperature environment of burn-in ovens, maintaining stability and consistency across long test durations. In large systems, this uniformity across thousands of channels reduces variability and simplifies maintenance planning.

Careful relay selection is therefore essential. Designers of test and measurement systems must balance precision requirements at low voltages with insulation needs at high voltages. Relays optimized for one domain often compromise performance in the other, which makes selection even more critical. Reed relays resolve this by offering dedicated variants: compact low-voltage models with minimal parasitics and high-voltage versions rated for switching above 1.5 kV and withstanding several kilovolts of isolation. This allows designers to build mixed-voltage systems with confidence, using the same reliable reed relay technology throughout the architecture.

High Voltage Isolation

High Current Pulse Handling

Summary

Burn-in testers challenge every aspect of relay performance. At low-voltage, accuracy can be compromised by resistance drift, parasitics, and contamination. At high-voltage, isolation and leakage risks threaten both safety and data integrity. Across both domains, long-duration thermal stress demands endurance.

Reed relays solve these issues with sealed, stable contacts, compact high-dielectric construction, and reliable timing over millions of operations. They deliver the precision, isolation, and longevity that burn-in systems require.

Standex Detect amplifies these advantages with a broad portfolio:

- SIL, MS, and UMS series for compact, low- voltage precision switching in THT style.

- CRR series with ceramic base for low EMF in SMD mounting.

- SHV, KT, and BH series for high-voltage isolation up to several kilovolts.

- BE and MRE series for shielded, low-noise signal switching or higher current pulse handling.

Together, these families cover the full spectrum of burn-in test needs. Backed by Standex’s proven supply stability and application engineering expertise, they provide a dependable foundation for reliable burn-in testing.

Source: Standex Detect.