Modern data centers demand uptime, security, and energy efficiency. Sensor integration delivers real-time monitoring, automates processes, and prevents failures. Applications span cooling systems, rack security, and room-level monitoring, building safer, greener, and future-ready data centers.

If there are particular areas you need help with, feel free to skip to any of the following sections:

- Introduction

- Why Sensors Are Essential in Modern Data Centers

- Proximity Sensors: Securing Access and Enhancing Safety

- Liquid Level Sensors: Keeping Cooling Systems in Check

- Energy Efficiency with Reed Technology

- Applications Across the Data Center

- Best Practices for Sensor Integration

- Why Choose Standex Detect?

- Conclusion

Introduction

Data centers are the backbone of today’s digital infrastructure, powering everything from cloud computing to AI workloads. As these facilities grow in complexity, engineers face mounting challenges: maintaining uptime, ensuring security, and managing thermal loads. One of the most effective strategies for addressing these challenges is integrating sensors into data center design. Sensors provide real-time monitoring, automate critical processes, and help prevent costly failures.

In this blog, we’ll explore how proximity sensors secure racks and cabinets, enable power interlocks, and withstand harsh environments, while liquid level sensors maintain coolant levels in immersion tanks and HVAC systems. Reed Sensors are a passive technology which means zero power consumption, reducing energy load within the data center while supporting sustainable, low-energy data center designs.

Check out the full list of Standex’s testing and certifications:

- ISO 9001 Certified

- IP67 Rated

- UL Listed

- RoHS Compliant

- REACH Compliant

Why Sensors Are Essential in Modern Data Centers

Data centers operate under strict environmental and security conditions. Even minor disruptions, such as unauthorized access or cooling system failure, can lead to equipment failure, data breaches, and significant financial impact. Sensors offer a proactive solution by:

- Monitoring physical access to racks and cabinets

- Detecting liquid levels in cooling systems

- Providing redundancy during power outages

- Reducing manual intervention for routine checks

By embedding sensors into the infrastructure, engineers can create smarter, more resilient data centers.

Proximity Sensors: Securing Access and Enhancing Safety

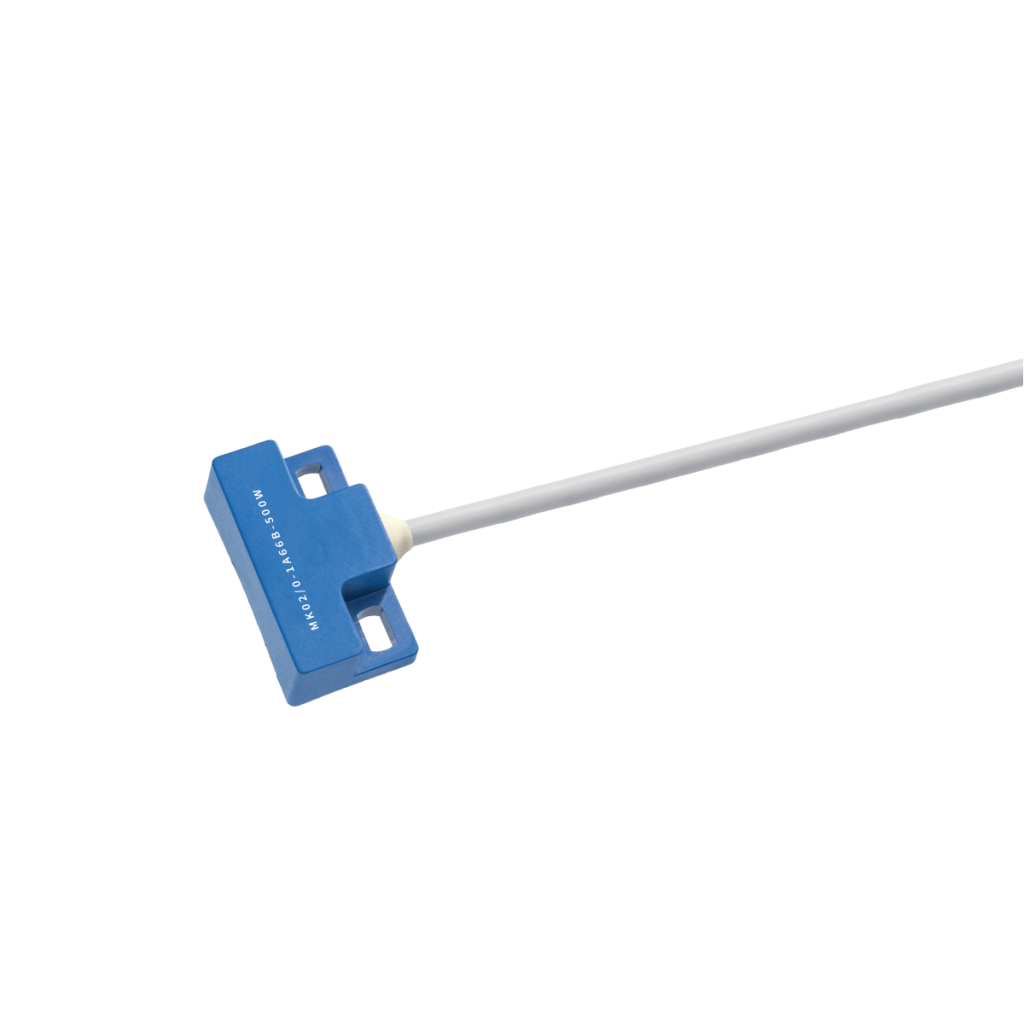

Security breaches and accidental maintenance errors can compromise sensitive equipment. Magnetic and ferrous proximity sensors are ideal for monitoring cabinet doors, gates, and rack positions. These sensors ensure that power is cut off during maintenance and alert operators to unauthorized access.

Key Advantages of Magnetic Proximity Sensors

- Passive Components: Easy installation without complex wiring.

- Power-Outage Resilience: Operates even when the system loses power.

- Environmental Durability: IP67 rating ensures reliable performance near HVAC systems.

- High Circuit Isolation: 1kV isolation for enhanced safety.

- Long-Term Reliability: With over 10 million switching cycles the sensors will last longer than the equipment they serve

Recommended Sensors

Liquid Level Sensors: Keeping Cooling Systems in Check

With increasing computing demands and rising rack densities, liquid cooling is becoming standard in high-performance data centers for thermal management. Float-based liquid level sensors offer a cost-effective and reliable solution for monitoring coolant levels in immersion tanks, chillers, and HVAC systems.

Advantages of Float-Based Liquid Level Sensors

- Accurate Detection: Prevents false triggers

- Fluid Compatibility: Works with various coolant types.

- Flexible Mounting: Top, bottom, and side mount options.

- Logic Options: Normally Open (NO) or Normally Closed (NC) configurations.

- Direct Switching: 100W options for line-level control.

Recommended Sensors

Energy Efficiency with Reed Technology

Data centers consume enormous amounts of energy, making efficiency a top priority. Reed switch technology offers a unique advantage for engineers designing low-power systems:

Advantages of Reed Technology

- Zero Power Consumption in Passive State: Reed switches remain completely passive until activated by a magnetic field, unlike other sensing technology that requires constant power.

- Noncontact Actuation: Switching occurs via magnetic control, reducing standby energy draw. Magnetic activation is a noncontact activation reducing the wear of mechanical components.

- Sustainability Benefits: Lower energy usage aligns with green data center initiatives and reduces operational costs.

By leveraging reed technology in proximity and liquid level sensors, engineers can easily implement sensors for monitoring that meet the performance and sustainability goals within data centers.

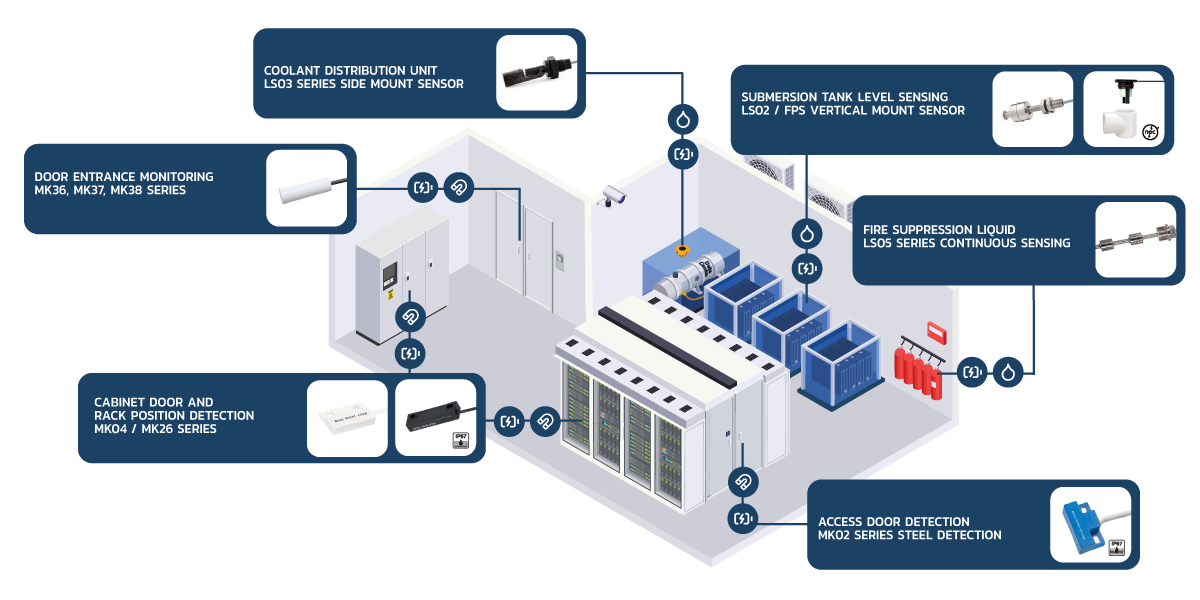

Applications Across the Data Center

Sensors play a vital role in maintaining efficiency, security, and reliability across every corner of the data center. From cooling systems to access control, proper integration ensures smooth operations and proactive management.

Below are key sensor integration application areas where sensors make the biggest impact:

- Immersion Cooling Tanks: Maintain optimal fluid levels for thermal management.

- Chillers and HVAC Systems: Prevent overheating and ensure airflow efficiency.

- Rack and Door Monitoring: Secure sensitive equipment from unauthorized access.

- Room-Level Control: Enable automated alerts for environmental changes.

Best Practices for Sensor Integration

Integrating sensors into data centers requires careful planning to ensure reliability, efficiency, and security. Following best practices can help you avoid costly downtime and maximize performance. Here are key guidelines to keep in mind:

Plan for Redundancy:

- Use dual-channel sensors for critical systems.

Ensure Material Compatibility:

- Match sensor materials with coolant chemistry.

Leverage IP-Rated Devices:

- Protect sensors from dust and moisture.

Combine Security and Safety:

- Integrate proximity sensors with power interlock systems.

Why Choose Standex Detect?

- Engineer-to-Engineer Collaboration: We work directly with your technical teams to co-develop solutions that meet your exact data center requirements, ensuring seamless integration and performance. From discrete sensors to integrated assemblies, tailored for rack-level access control, environmental monitoring, and infrastructure automation.

- Agility & Speed: Fast response to evolving data center architectures, security protocols, and environmental monitoring requirements.

- Reliability: Components tested for continuous operation in high-density, high-temperature, and EMI-prone environments, ensuring uptime and system integrity.

- Scalability: From edge deployments to hyperscale data centers, our solutions scale with your infrastructure and integration needs.

- Innovation: Smart sensing, miniaturization, and ruggedized designs for next-generation data center platforms and intelligent infrastructure.

- Custom + Standard Solutions: Whether you need off-the-shelf reliability or a fully customized assembly, we deliver both, with precision and speed.

Conclusion

As data centers evolve toward AI-driven automation, sensors will play a pivotal role in predictive maintenance and energy optimization. Expect advancements in smart sensors that combine multiple functions, such as temperature, vibration, and liquid level detection, into a single device. For engineers designing modern data centers, sensor integration is no longer optional, it’s essential. By deploying proximity sensors, liquid level sensors, and energy-efficient reed technology, you can build facilities that are safer, more efficient, and future-ready.

Ready to Optimize Your Data Center?

Standex Electronics Detect offers a full portfolio of sensors for data centers. Contact us today to discuss your application or request a quote.